No. 1 CMMS for maintenance and higher efficiency

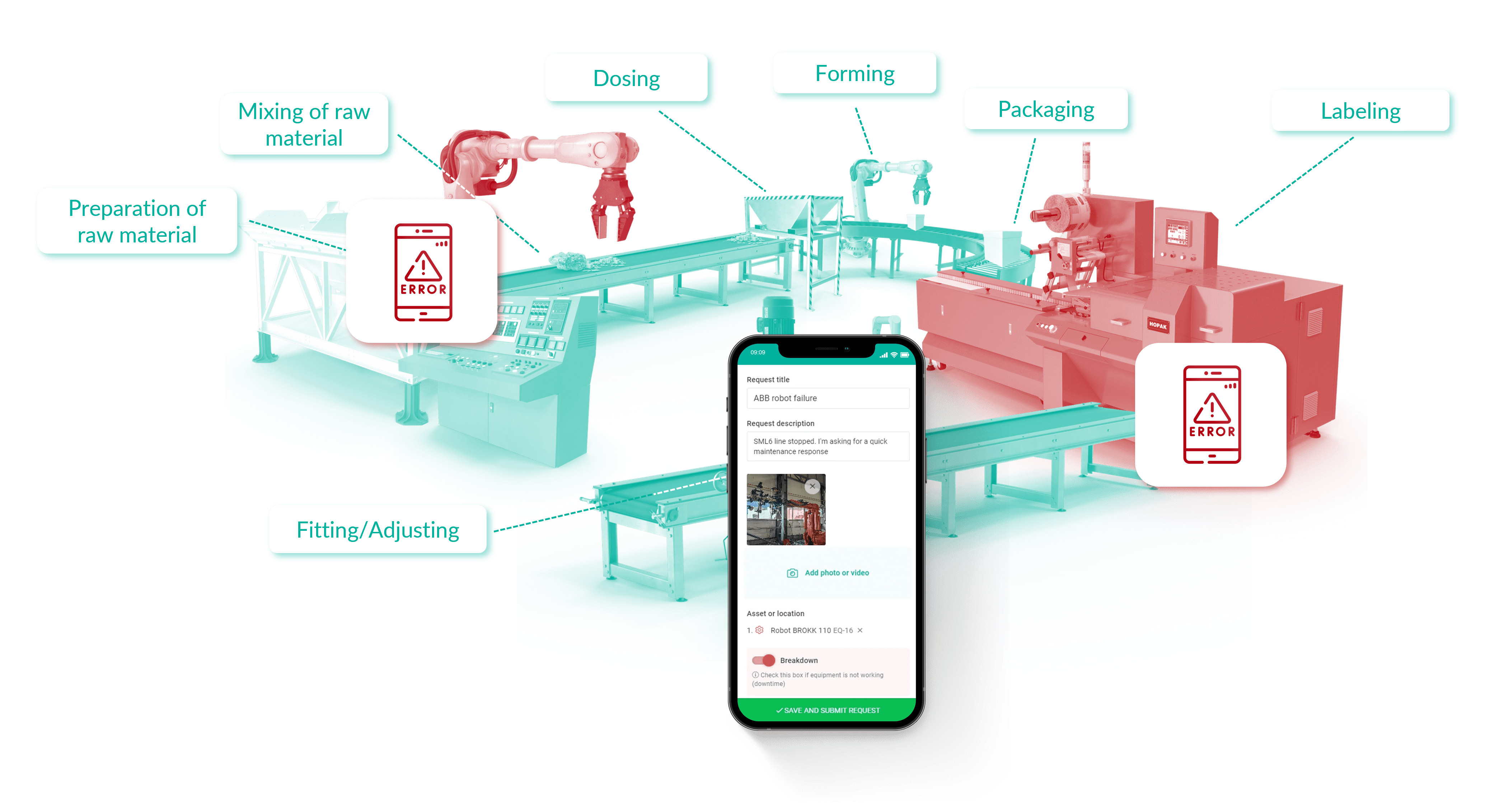

QRmaint is a fully mobile CMMS software that enables simple task handling for maintenance technicians, providing managers with an excellent solution for work coordination and task management.

Join 500+ satisfied customers

Individual approach to each client and a very open and helpful QRmaint team makes cooperation with us is a pleasure.

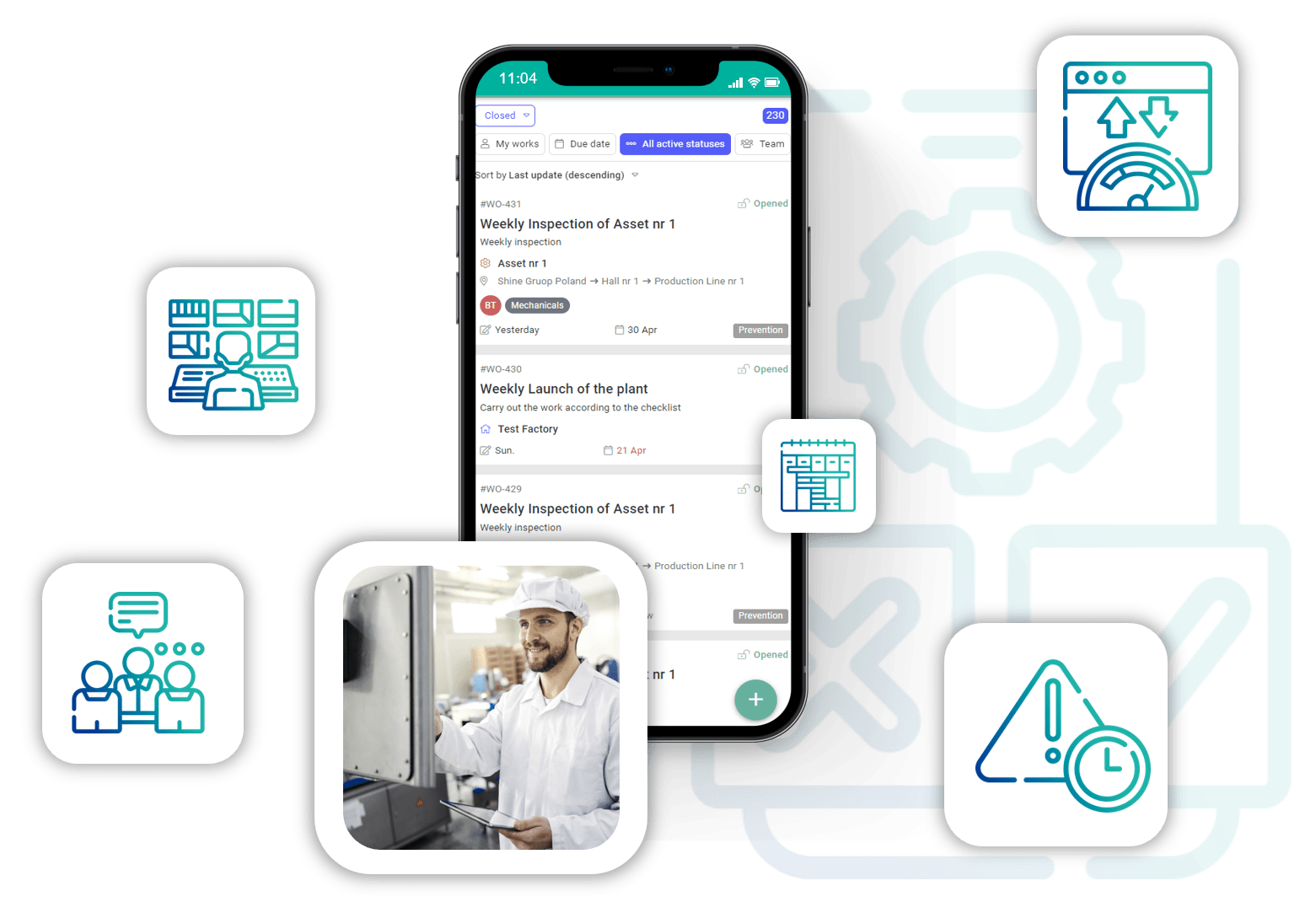

Simple for technicians

The tasks of UR technicians and field workers have never been simpler. QRmaint unlocks data flow and increases team mobility and productivity.

- Complete tasks directly from your phone or tablet

- Scan QR codes of devices to see their history

- Communicate with your team

- Receive notifications

- Check parts availability

- Add multimedia, photos of defects and record service and repairs

Beneficial for managers

Managers and supervisors can take full control of daily operations. QRmaint enhances scheduling capabilities, improves communication and provides long-term benefits for your business.

- Control the time and cost of completing tasks

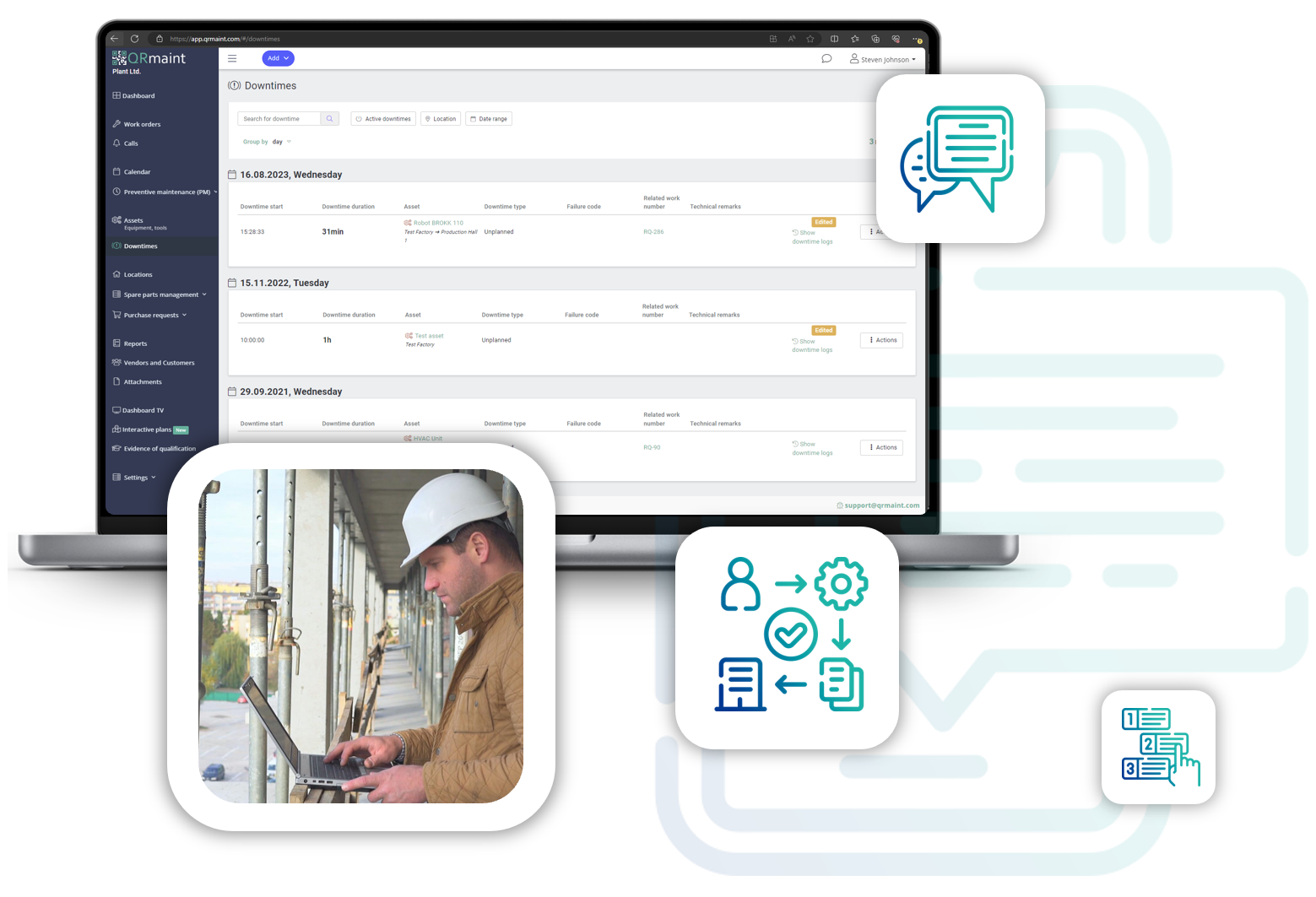

- Monitor equipment availability – downtime

- Generate and view reports

- Analyze fixed asset history

- Make decisions based on real data

- Manage maintenance teams

- Plan and schedule tasks

It’s easy to get started with QRmaint

And it’s free for 14 days. No credit card, no commitment.

Mobile Work Order

Task management is the main module of QRmaint application’s CMMS system, which effectively reduces work with paper documentation and printed forms. At the same time, it transparently combines numerous functions to streamline processes related to the control of personnel, infrastructure, equipment and machinery.

- Centralizes and automates the process of managing, assigning, tracking and finalizing work orders

- Provides continuous insight into the status of tasks

- Facilitates communication between team members

- Enables efficient allocation of resources

- Ensures timely execution of maintenance, service and upkeep activities

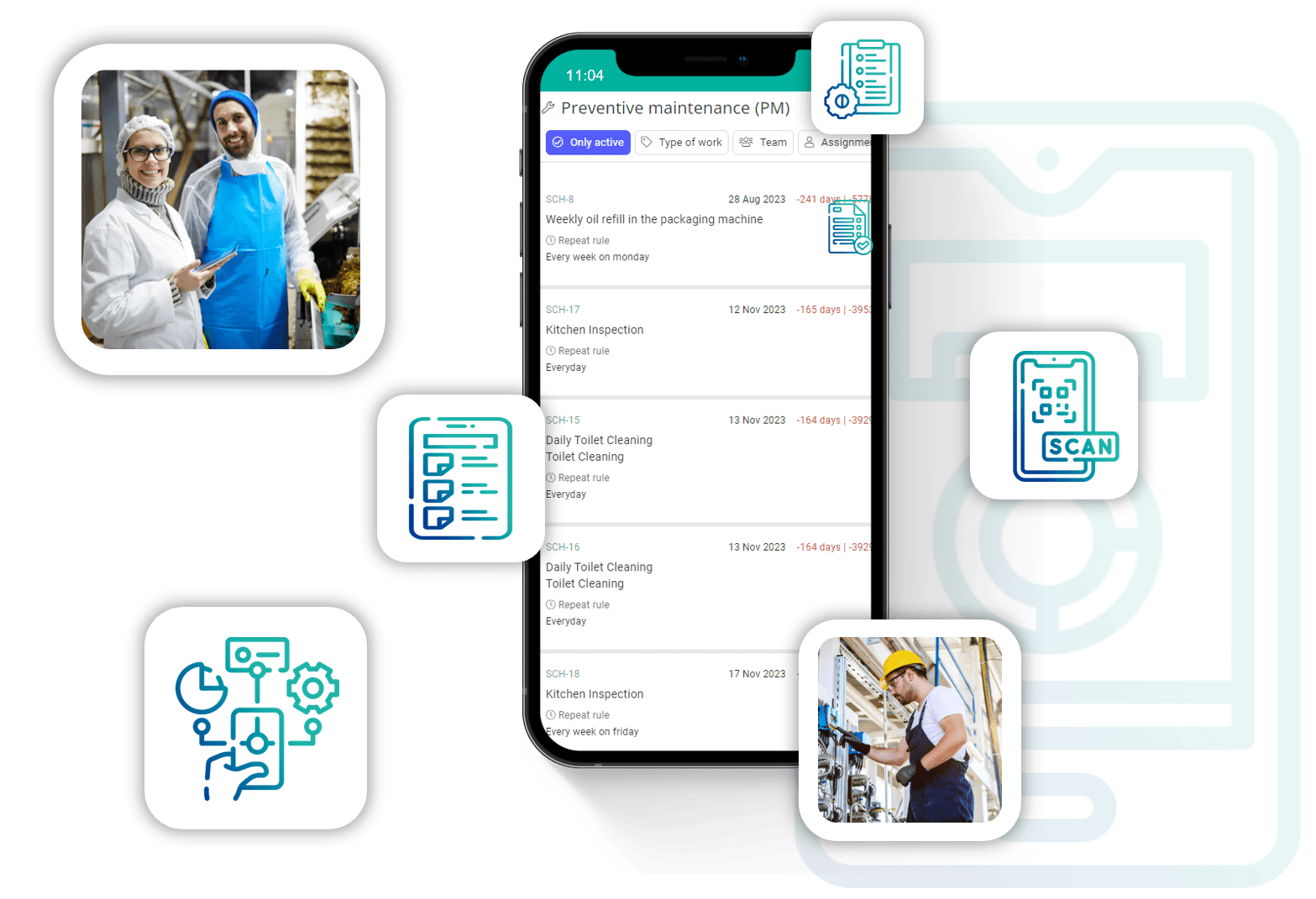

Preventive maintenance

The CMMS system enables preventive maintenance. The application supports the execution of Preventive Maintenance (PM) and management of systems and operation cycle.

- It proactively supports the creation of plans and execution of maintenance tasks at regular intervals.

- This helps prevent equipment failures and extend equipment life.

- Minimizes downtime by scheduling maintenance tasks in advance.

- Automates scheduling based on predefined criteria such as time, utilization or condition.

- Reduces the risk of unexpected failures and costly repairs.

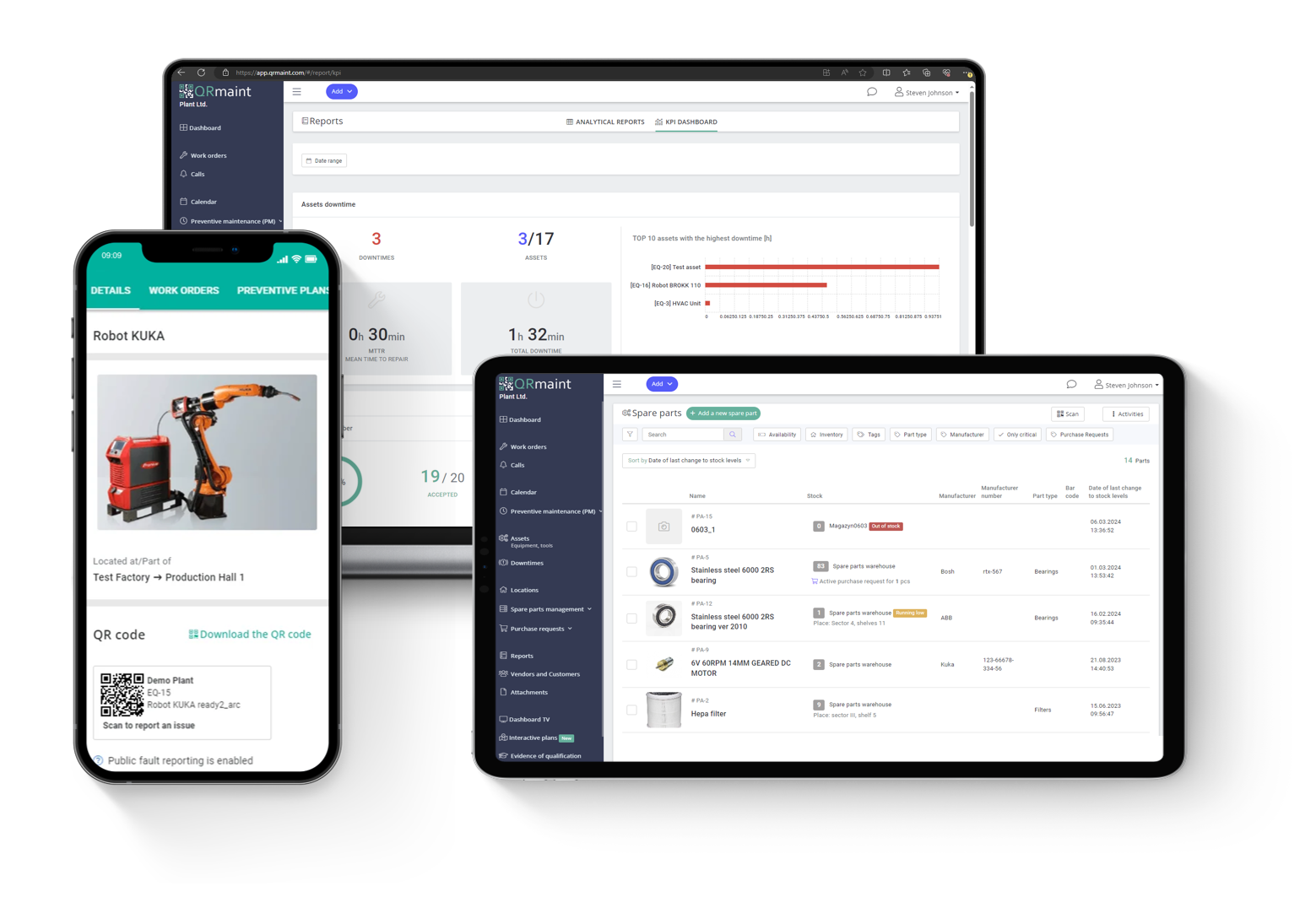

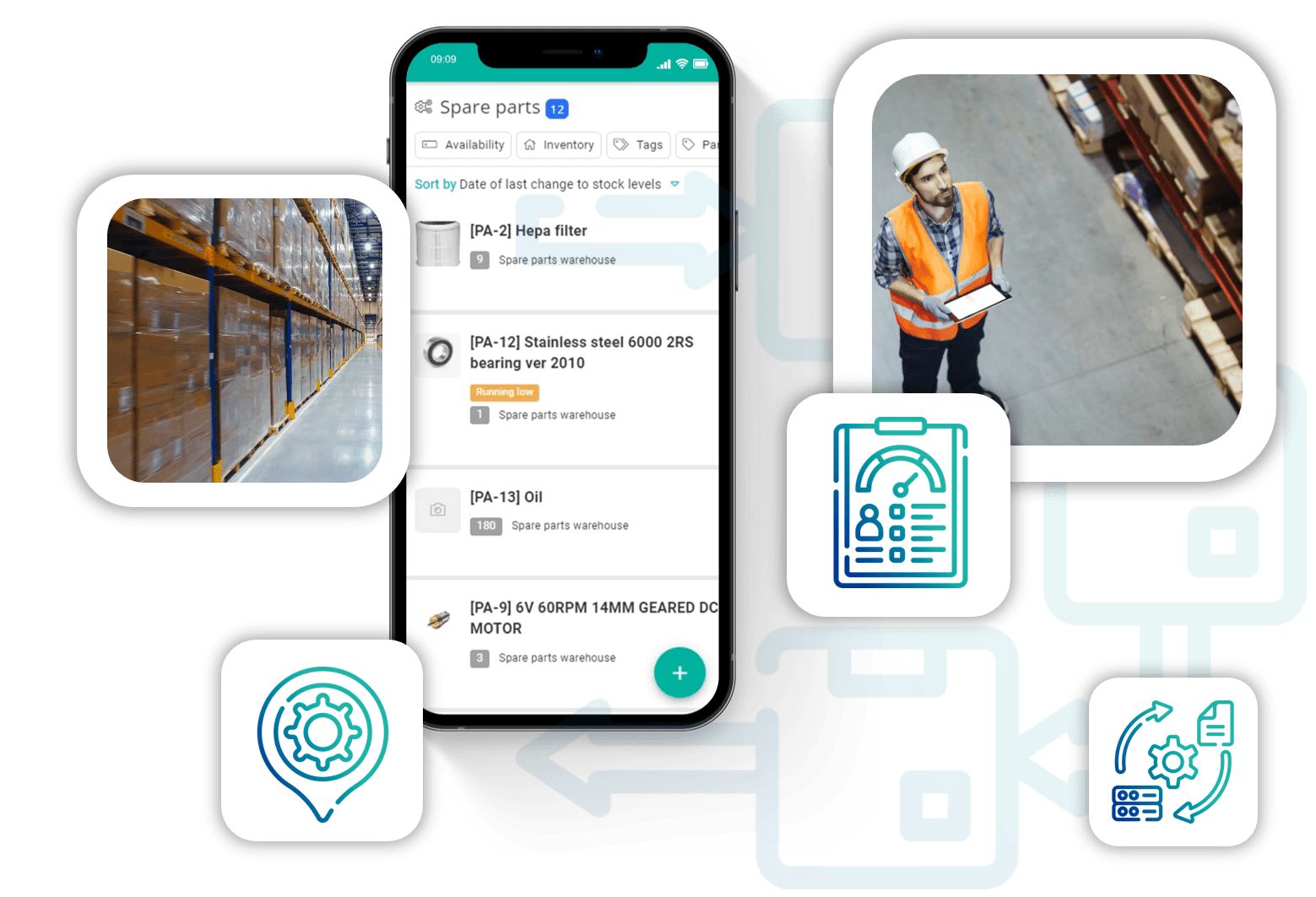

Warehouse and parts management

QRmaint CMMS integrates warehouse operations and handles the material flow of spare parts and supports warehouse management. The application automatically pairs spare parts from the warehouse with ongoing maintenance tasks.

- Manage your inventory of spare parts, consumables and

- Tracks inventory levels

- Organizes the order of materials to be taken from the warehouse

- Helps manage suppliers and records inventory usage

- Ensures availability of necessary parts for maintenance and service work

- Optimizes inventory costs and minimizes machine downtime

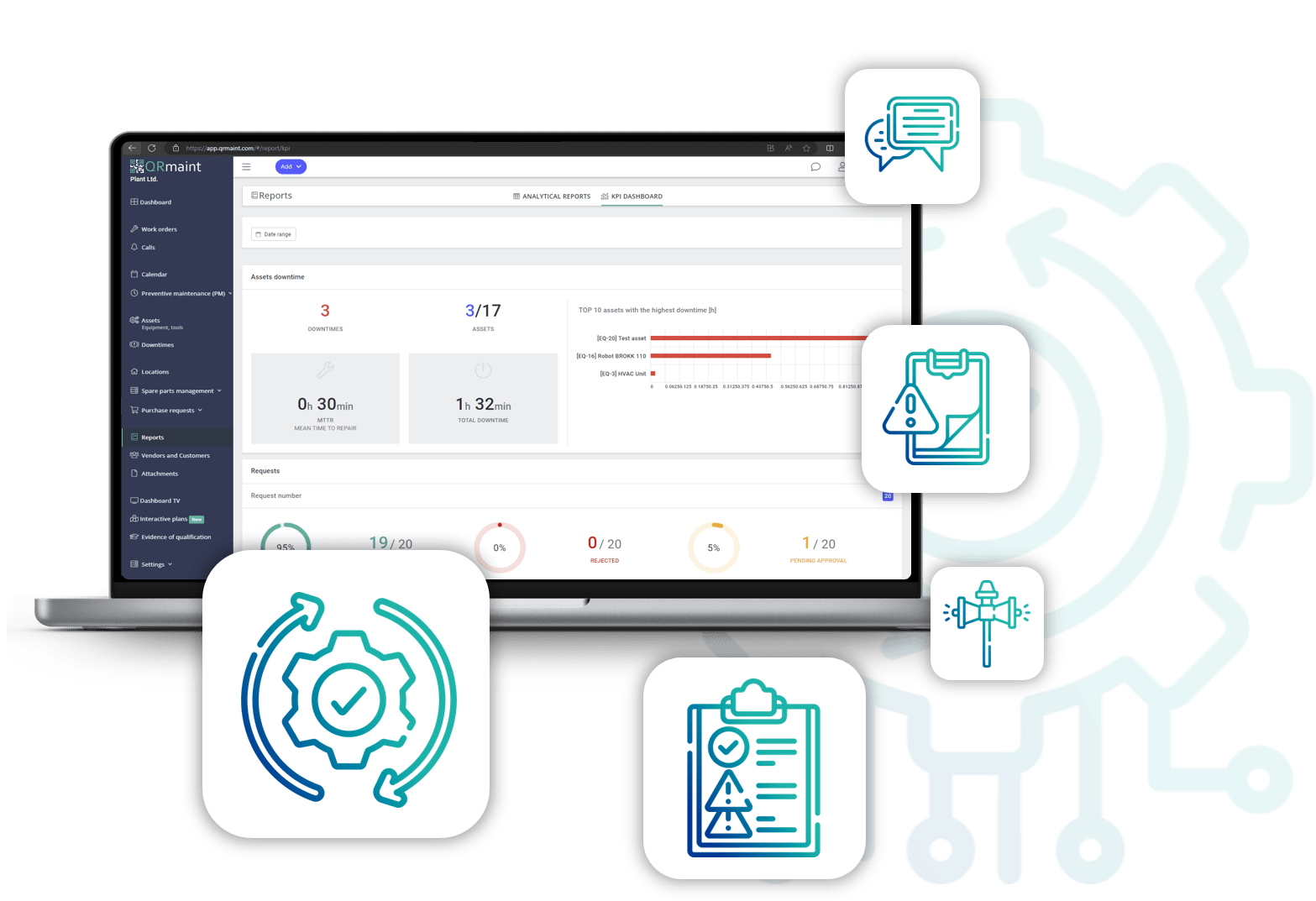

Reports and analysis

The QRmaint CMMS system application uses data collected during service and maintenance activities. With QRmaint, the performance of equipment and machinery can be measured. The system allows you to generate reports on demand.

- Identifies trends and predicts equipment failures

- Optimizes maintenance schedules based on historical data

- Measures key performance indicators (KPIs) such as uptime and maintenance costs

- Enables continuous improvement of maintenance processes and operational efficiency

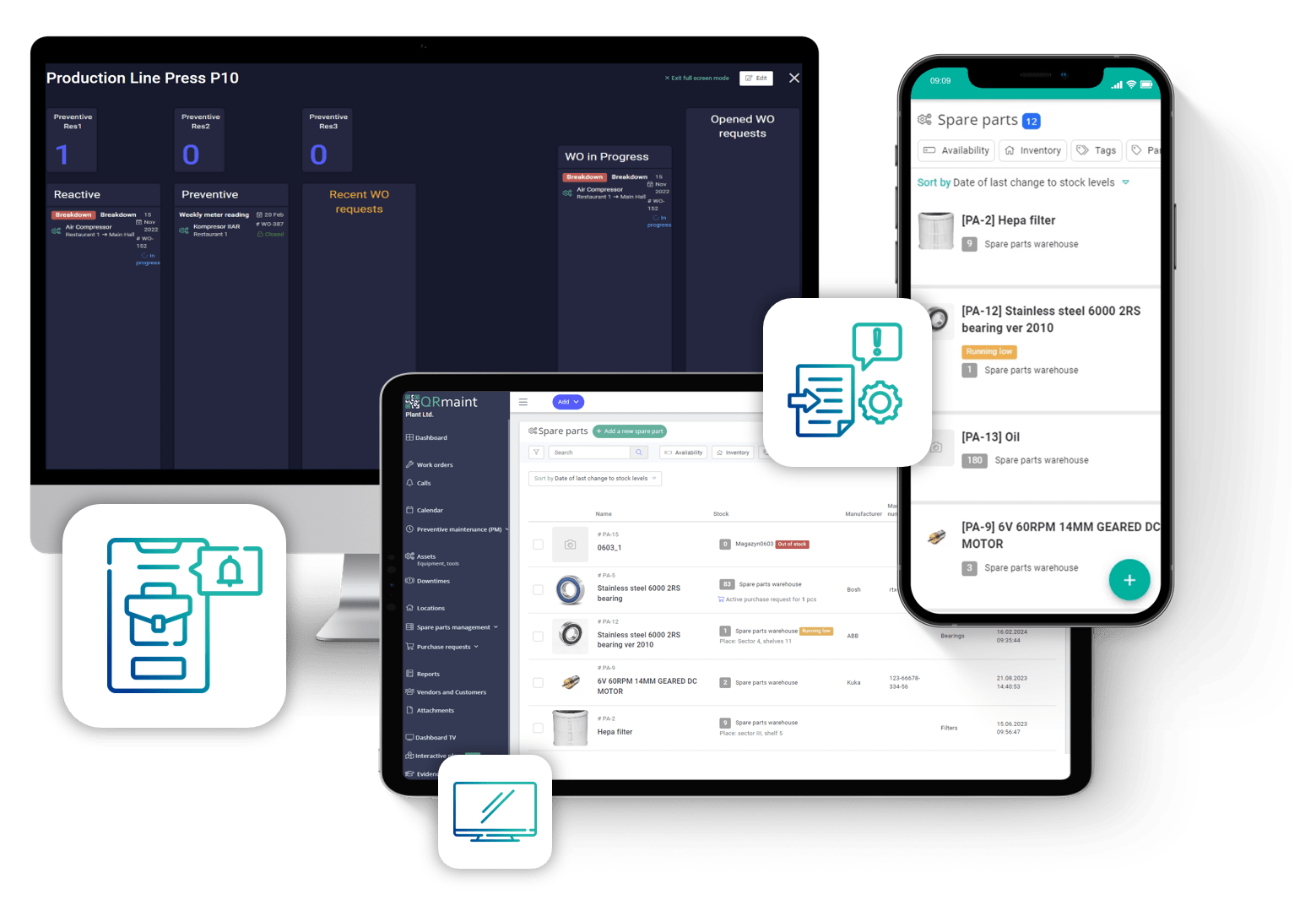

Versatility across multiple devices

The system’s availability on multiple devices is one of the cornerstones of modern facility management.

Whether it’s a desktop computer, a tablet carried by technicians in the field, or a smartphone used for quick updates, the versatility of the QRmaint application ensures that important information is never out of reach.

The versatility of access across multiple devices translates into smoother operations, better communication and increased efficiency in facilities management.

Multipurpose use

QRmaint CMMS was developed specifically for maintenance tasks. Its versatile application goes far beyond the typical system for maintenance departments.

- The system supports monitoring and tracking of asset information such as location, maintenance history, warranties and documentation

- Provides a central repository for system data

- Facilitates information-based decisions on maintenance, replacement and investment in new equipment

- Improves plant and equipment performance and reliability

The multifunctionality of the QRmaint application allows the solution to be adapted to other processes related to technical management of real estate, fixed assets, infrastructure and more.

Try it for free

Solutions QRmaint

Find out about the most important solutions and processes that can be handled together with QRmaint app

It’s easy to get started with QRmaint

And it’s free for 14 days. No credit card, no commitment.

Get to know the opinions of our clients!

The QRmaint CMMS system is a perfect solution for a number of industries, such as manufacturing plants, maintenance for real estate, chain stores, schools and all types of service providers. Have a look at what the representatives of different industries have to say about us.