CMMS Software for maintenance departments

Managing the maintenance process can be simpler and more effective. QRmaint is mobility-oriented and intuitive to CMMS Software. The price tag or a complicated implementation process will no longer be a barrier to anyone!

#1 Choice of technicians and managers

- Mobility and intuitiveness

QRmaint is a mobile CMMS that focuses on usability. This CMMS system was designed above all, to help everyone, not to obstruct technicians in their daily work or to hinder their maintenance services.

- An unbeatable price and trouble-free implementation

Thanks to QRmaint, the access to CMMS applications has never been easier. It only takes a few seconds to open an account to transform the maintenance at your production facility.

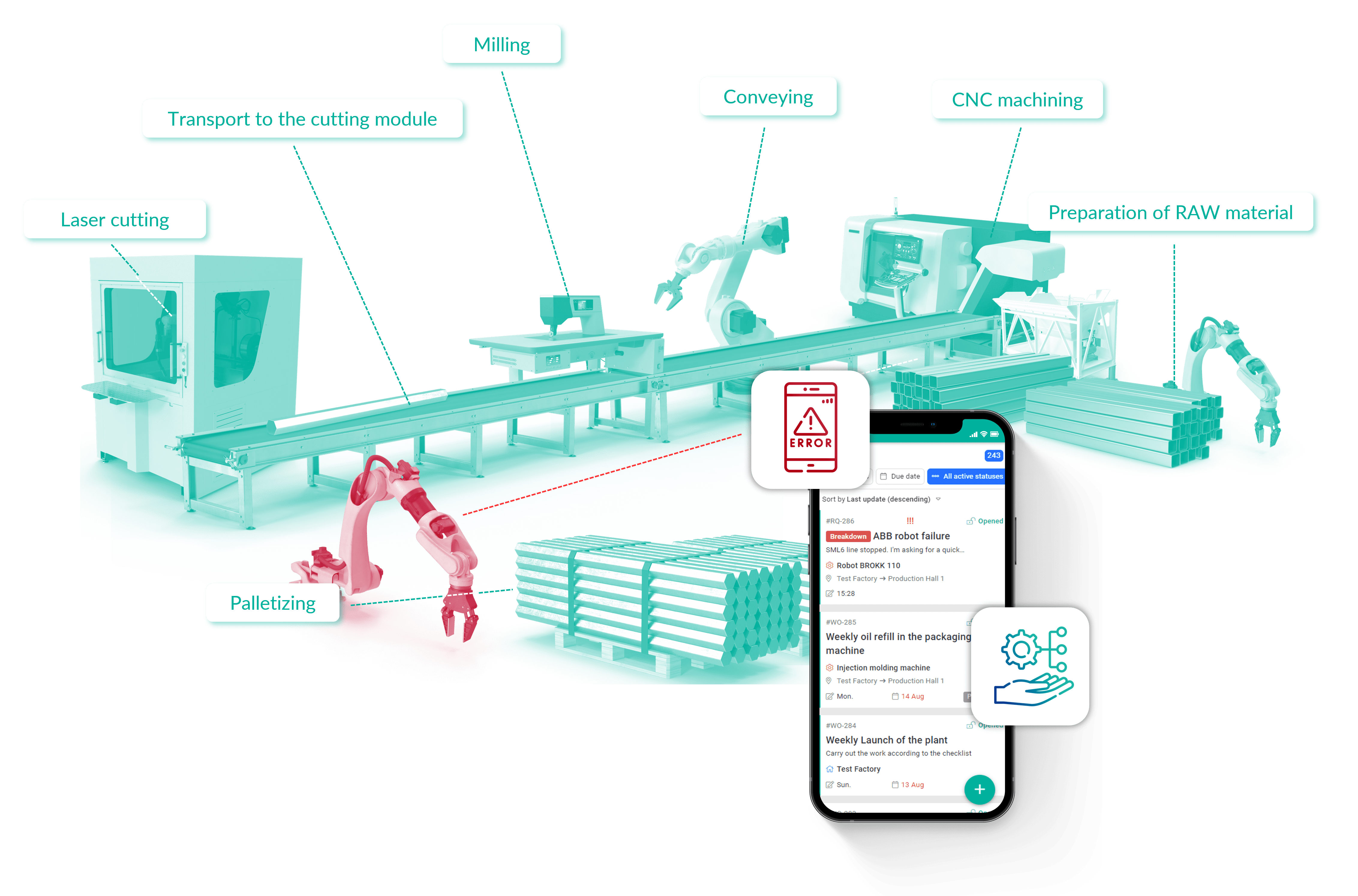

Simplify the maintenance of assets

- Gain full control over the condition of the machine park

Mobility and QR codes are the key to efficient maintenance at a production plant. Scan the QR code and get a full history of the machine, report a failure or handle the task assigned to you.

- Improve machines and equipment reliability

Efficient maintenance management will result in higher profits, less downtime and lower failure rates of equipment and machines. Recurring preventive maintenance with QRmaint CMMS is a safe bet!

It’s easy to get started with QRmaint

And it’s free for 14 days. No credit card, no commitment.

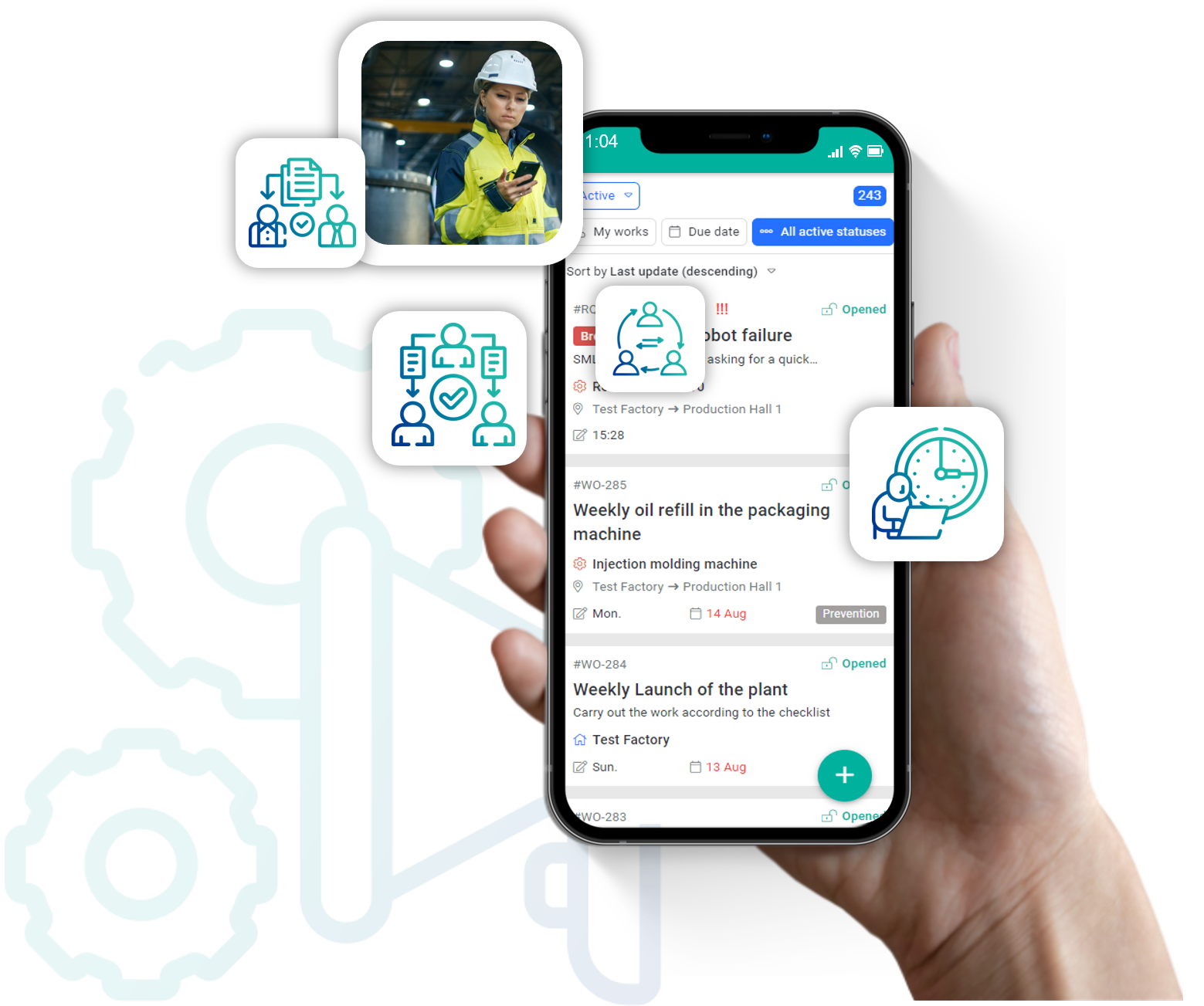

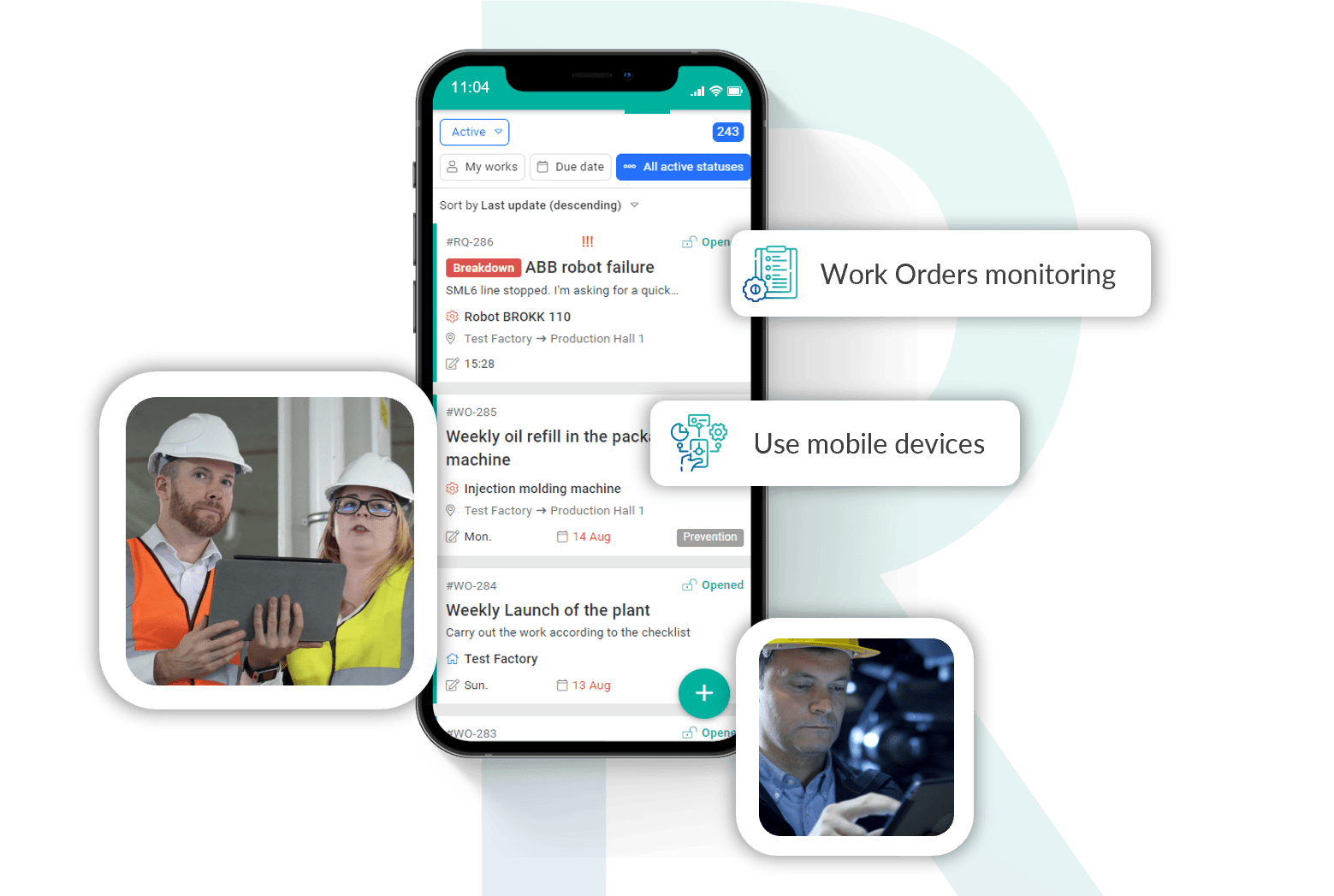

Handling work orders

- Improve cooperation between production line employees and the maintenance department

Usually breakdowns or defects are the first to be noticed by production line workers and operators. Providing a simple and quick method of reporting is the key to reducing machine downtime and reducing financial losses of the production plant.

- Notifications about a new failure, a defect or a problem

The so- called PUSH notifications or an e-mail to the mobile phone will instantly provide the maintenance team with information on a problem, so that they can quickly start working on it.

Make it easy to submit work requests

Streamlining the work order process is a must for effective maintenance management.

By utlizing user-friendly interfaces and intuitive features, our mobile CMMS systems make it easier for technicians and clerk workers to seamlessly submit work requests.

This is an ideal way to bring proactive maintenance work practices into the enterprise, production facility or for assets management in real estate. Employees are able to report issues quickly when the process is simple. Ultimately, our CMMS makes it easier to submit work orders, help improve maintenance performance and overall operational efficiency.

Try it for free

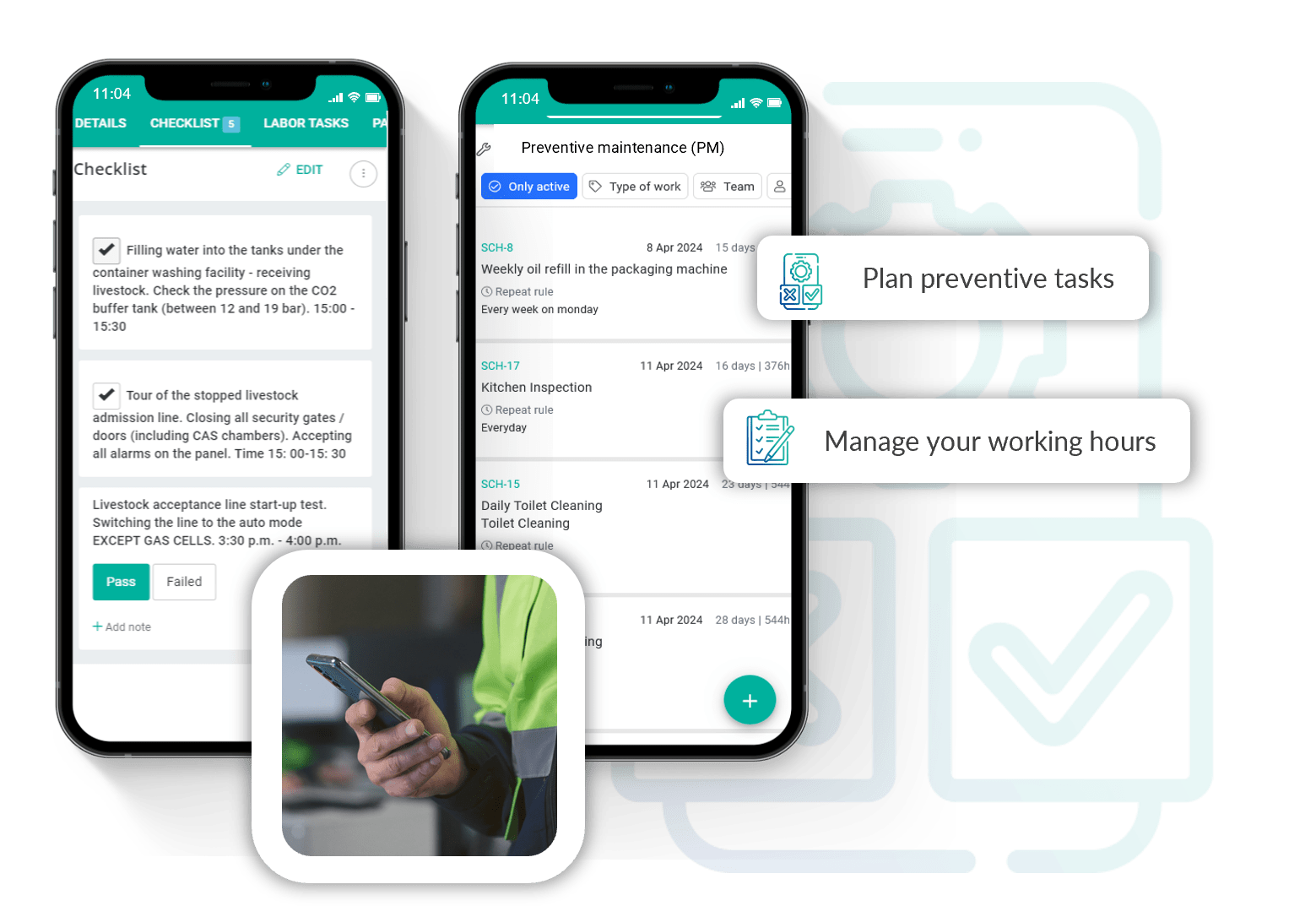

Easily schedule and automate preventive maintenance

- Preventive work orders based on a calendar or readings

Schedule inspections, reviews or other preventive work. The QRmaint CMMS software will then create periodical notifications and send you an email or a text message on a weekly, monthly, annually basis or even every other reading.

- Checklists

Add checklists for routine inspections, instructions, walkthroughs, safety checks, and other maintenance activities. For audit purposes, sign the checklist directly from the mobile QRmaint CMMS app.

- A graphical schedule

Use a clear, graphical schedule to easily see all scheduling preventive maintenance tasks not completed on time, those completed or planned.

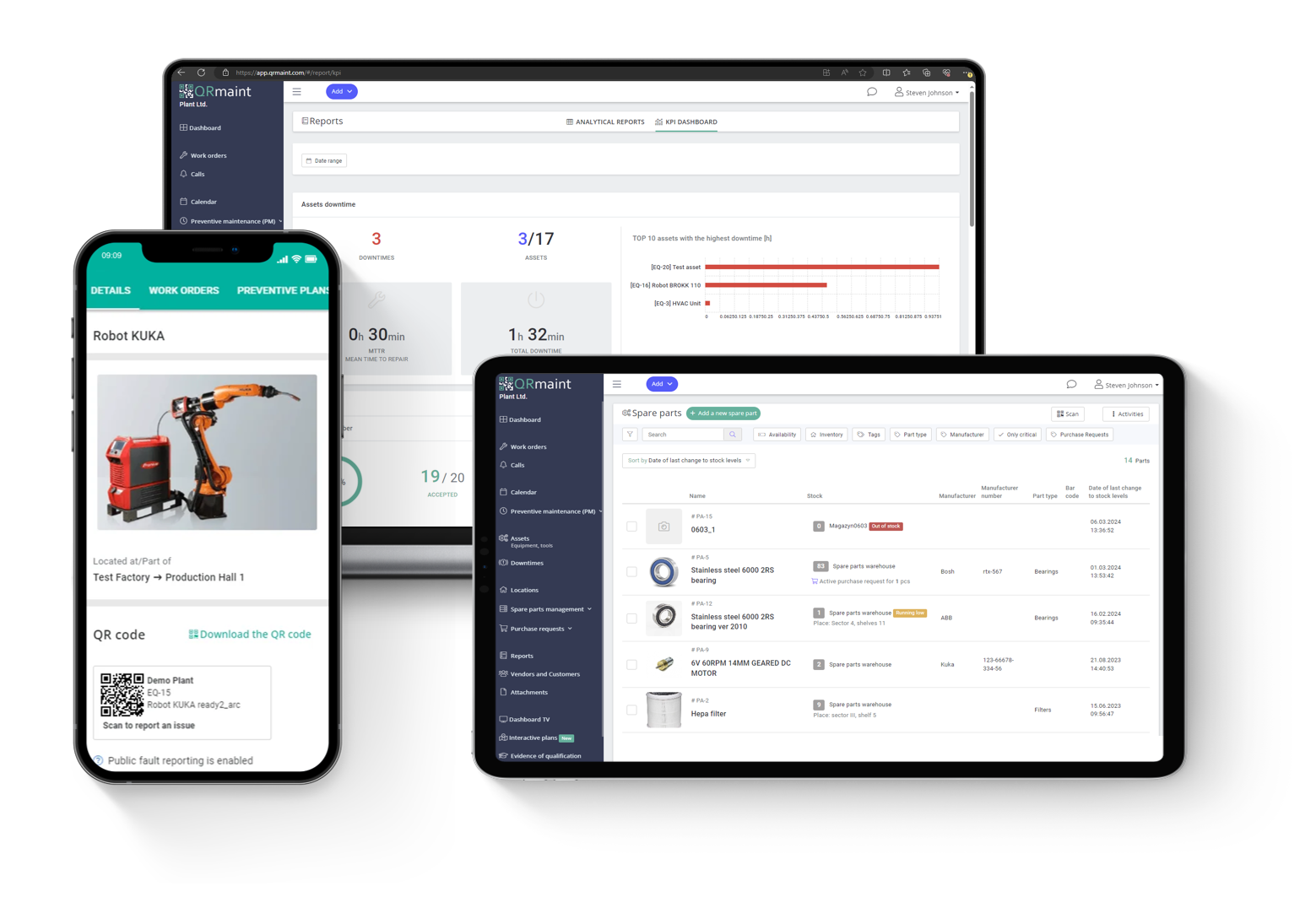

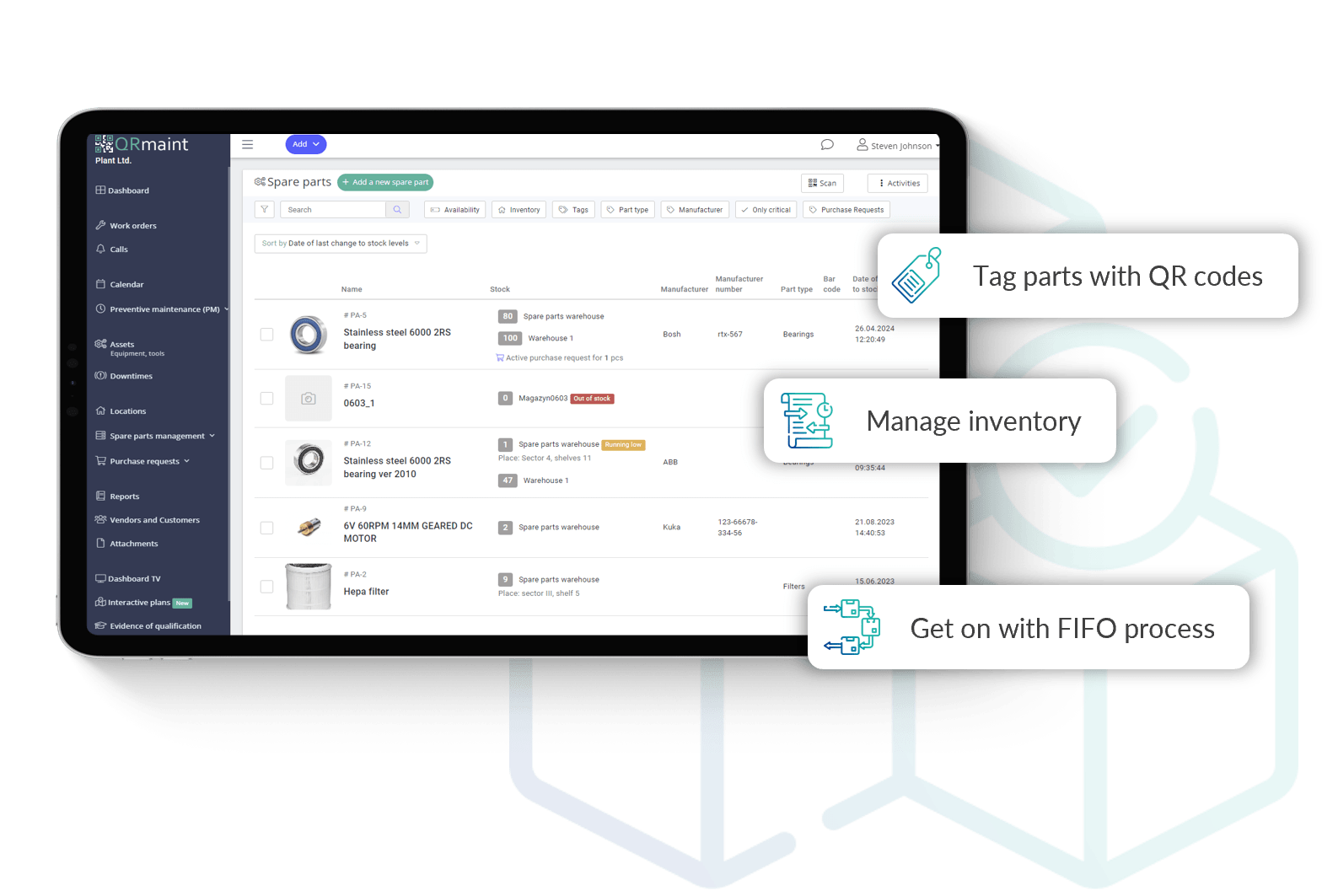

Try it for freeInventory management

- Barcodes and the QR codes

Use codes to simplify and automate the distribution and reception of spare parts.

- Monitor the minimum level of parts

Missing or insufficient amounts of spare parts when removing failures means longer downtime and financial losses. Set minimum stocks so that this never happens again.

- Full history of changes at the inventory

QRmaint CMMS software gathers and keeps in one place all the information of the operations affecting the inventory. You are always kept in the loop and up to date on which employee withdrew which spare part and for the purpose of which work order.

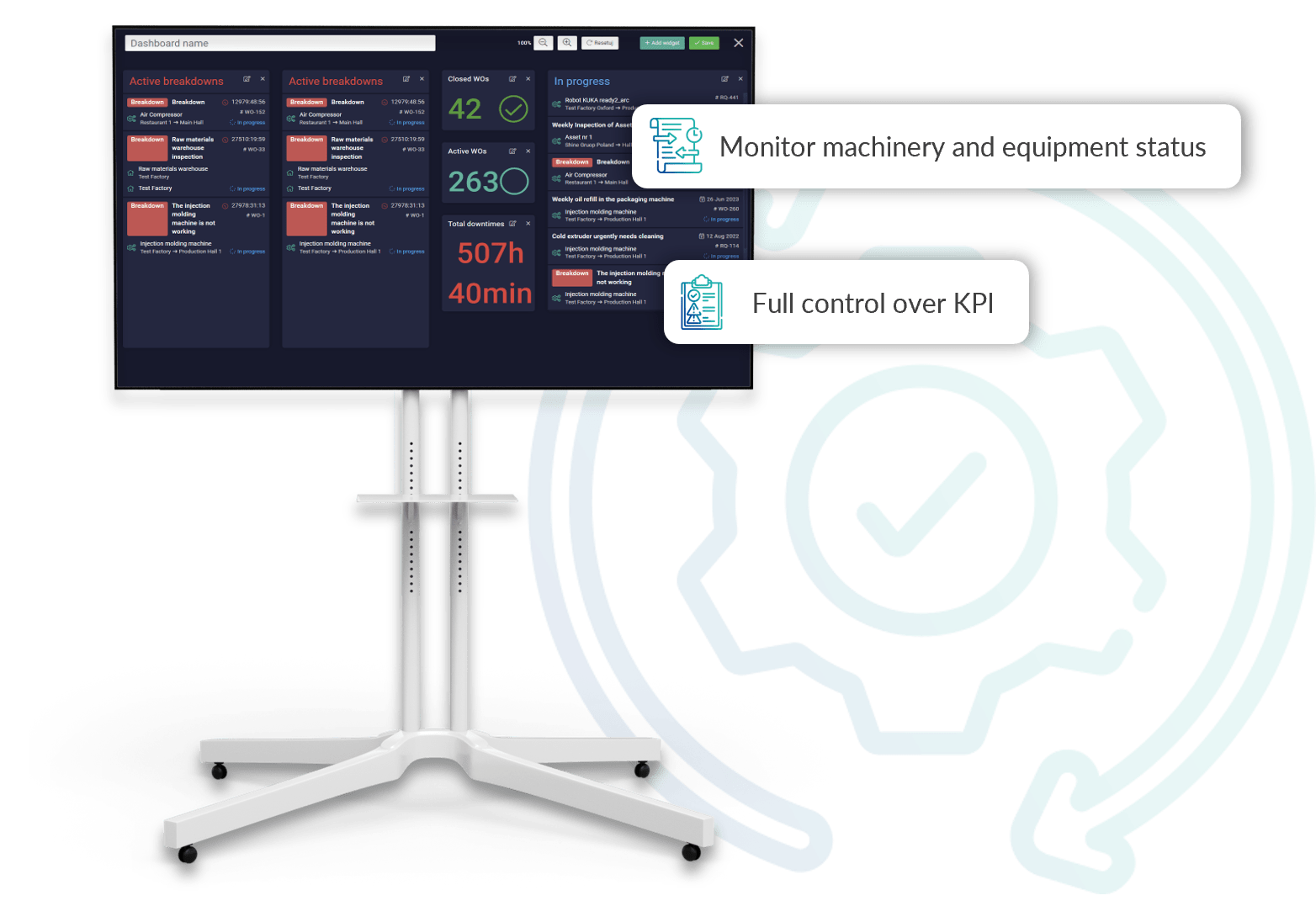

Dashboard TV

- Real-time machine park condition

Create your own dashboards for any location or production line to track the status of the machine park in real time.

- Improving communication and increasing productivity

The dashboard displayed in the technicians room or in the production hall is the easiest and most effective way to increase the productivity of the technical team and improve communication.

A glance at the TV set is enough to see what tasks are currently performed and by which technique, as well as what new reports have been received, and many other information that we can set ourselves according to our preferences.

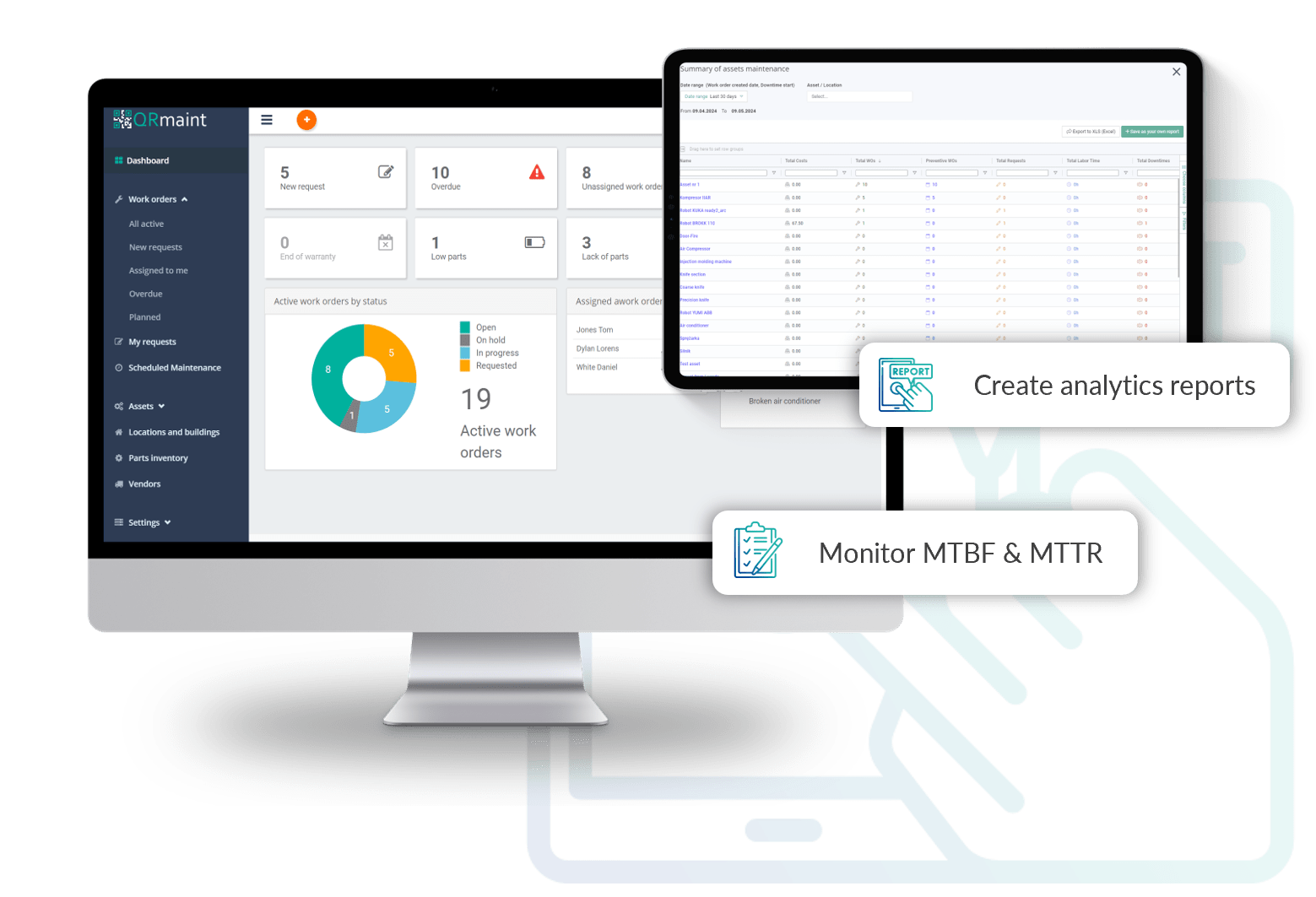

Try it for freeAnalyzing and reporting

- Analytical reports

The analysis of the functioning of the maintenance department plays a critical role in the successful implementation of the total productive maintenance (TPM). Reliable and detailed reports on the data gathered within the CMMS system are crucial when making decisions about preventive actions and the functioning of the manufacturing plant.

- KPI dashboard

The KPI dashboard in the QRmaint CMMS system is a place where you can track key indicators related to maintenance, such as MTBF, MTTR and other important information presented as a graph.

Try it for free

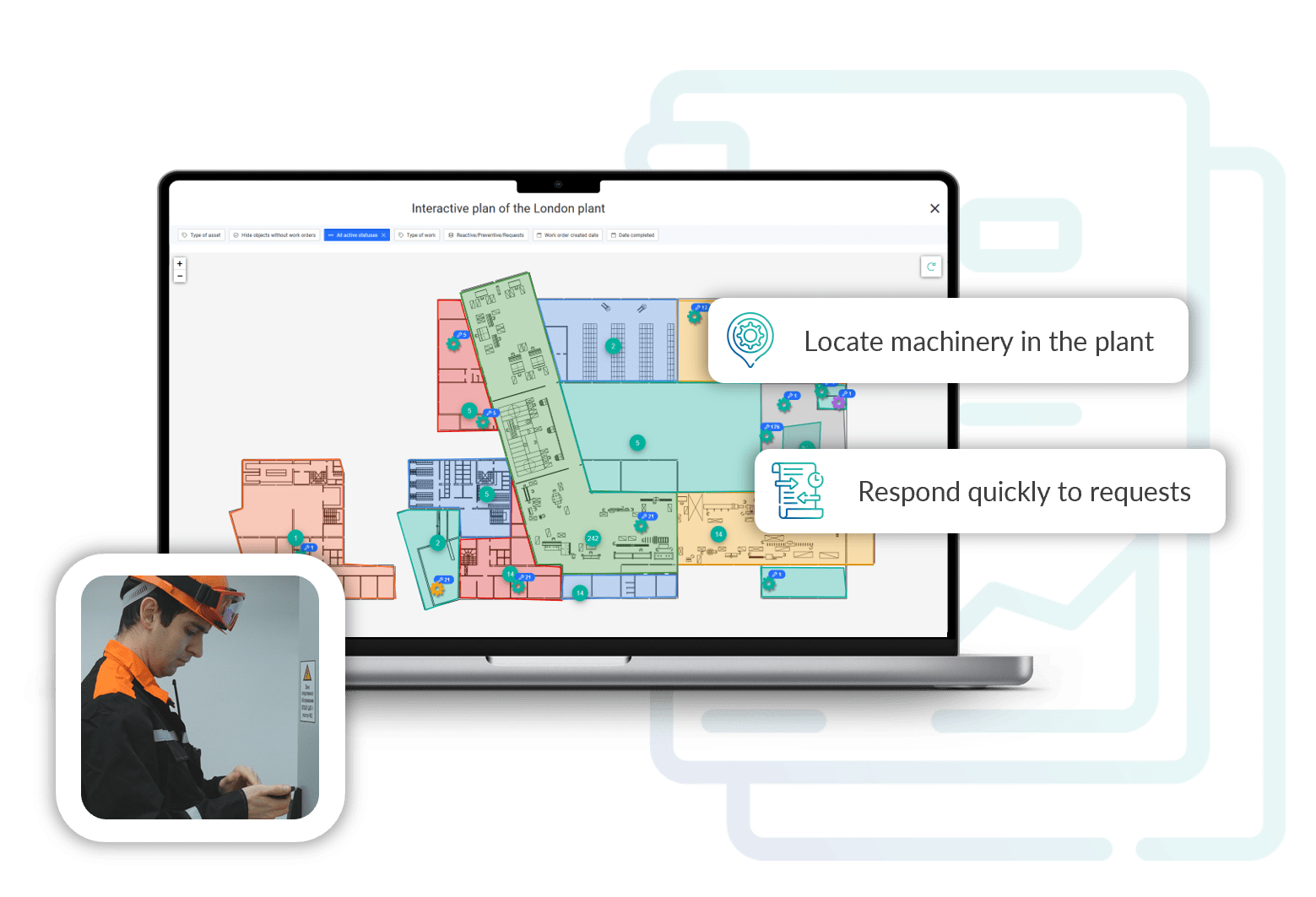

Interactive plans

One of the main advantages of interactive plans for production plant is their ability to synchronize various aspects of production, from inventory management to machine scheduling, in a consistent manner.

Here are the main advantages:

- Optimizing resource utilization: Interactive plans dynamically allocate resources based on real-time data and predictive analytics.

- Collaborative decision-making: These plans support collaboration between different departments and users, such technicians.

- Flexibility and responsiveness: With real-time monitoring and feedback mechanisms, production managers can quickly adjust schedules and workflows to meet changing market demands.

- Proactive problem solving: Interactive plans anticipate potential bottlenecks, material shortages or equipment failures.

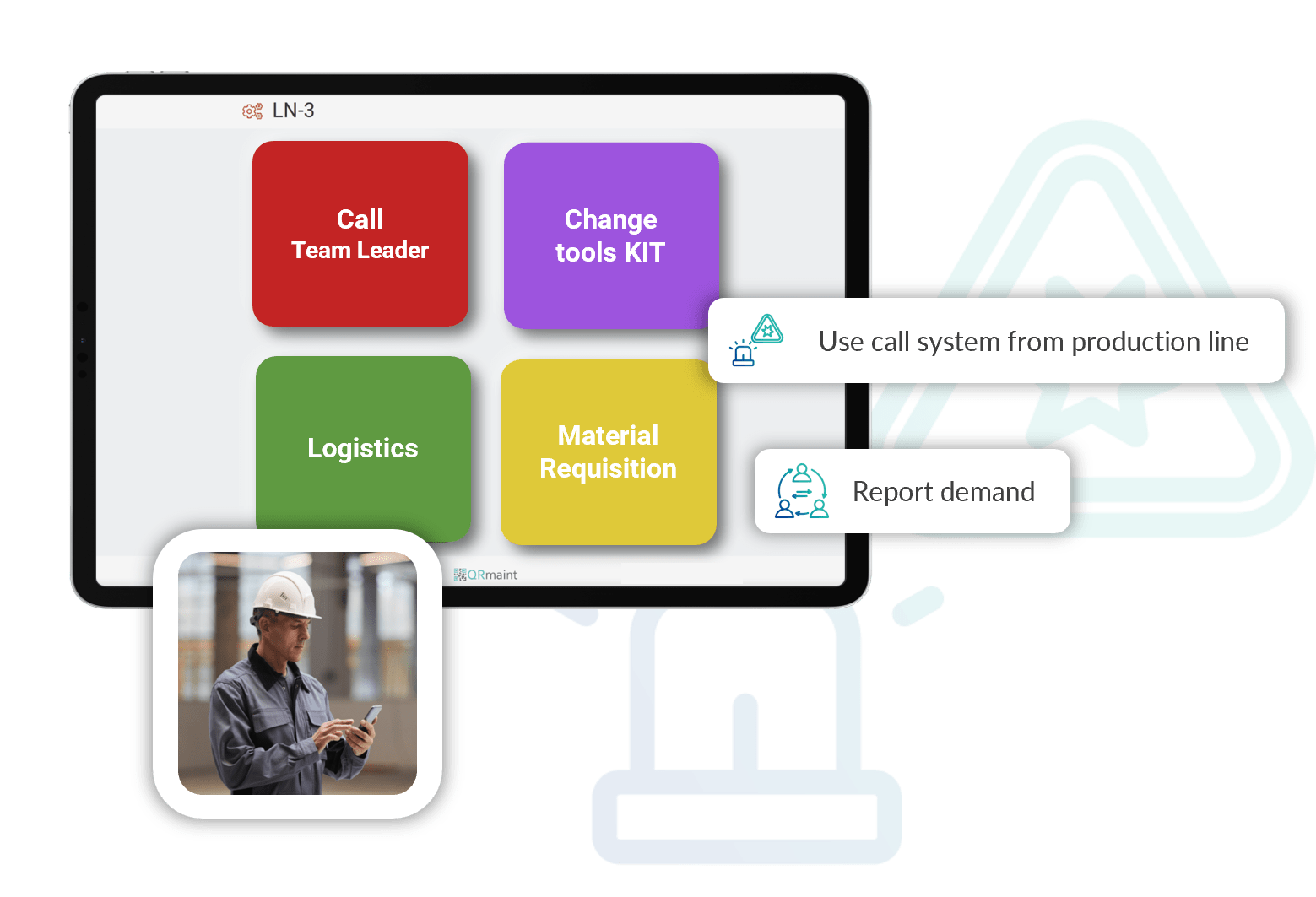

ANDON System

Our ANDON integrated warning system reduces response time by up to 40%-50%. Installation is easy for any manufacturing plant or any infrastructure area that requires close collaboration with the maintenance team.

- Minimize downtime, maximize savings: the system reduces inefficiencies, saving our customers time and money.

- Performance tracking: The Andon system records all calls, reminders, escalations and response times.

- Flexibility and responsiveness: With real-time monitoring and feedback mechanisms, operations staff can quickly report problems and equipment failures.

- User-friendly interface: Designed with an intuitive user interface, the ANDON system is easy to navigate and user-friendly, minimizing training requirements and enabling rapid adoption by production personnel of all skill levels.

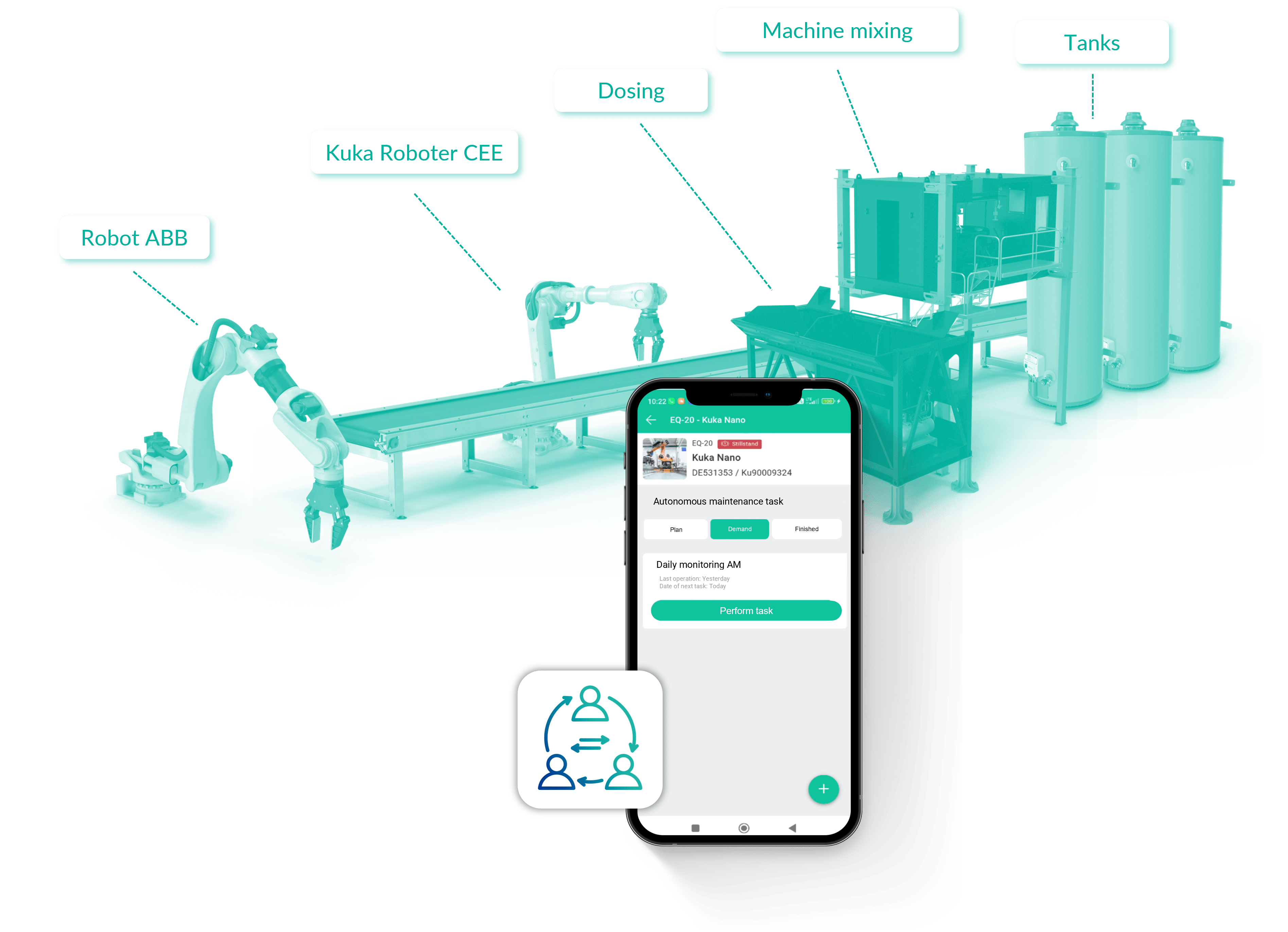

Autonomous maintenance

QRmaint CMMS system enables production workers to perform tasks efficiently. Employees can perform daily preparation tasks using checklists.

Operators can perform tasks such as cleaning machines and performing pre-work inspections to ensure compliance with HACCP (Hazard Analysis and Critical Control Point) regulations, which is extremely important in food production in the food industry. They also have the ability to check the condition of auxiliary, electrical and control equipment, which is part of every production line, regardless of the industry.

Operators can perform tasks according to a predetermined schedule or on demand. This allows for better quality control of the products produced.

Try it for freeIntegration of systems and technologies

QRmaint CMMS system allows integration with ERP systems. It has found favor with SAP users for years and has repeatedly become an alternative solution for replacing SAP PM and many other systems.

By integrating the QRmaint system with IoT connectors, sensors, infrared transmitters and receivers, maintenance technicians gain complete control in real time over the machinery fleet.

Try it for free

Wide range of applications

The scope of our system includes much more than just support for UR departments within a fleet. With its comprehensive features, QRmaint can be easily customized for tasks in FMCG, property or asset management, field services and maintenance.

Using QRmaint makes it possible to perform field services (FSP), which involves delegating tasks to technicians in remote locations to install, repair or service equipment and systems. Such tasks are of direct relevance to the energy, mining and rail industries.

Technicians can manage, as well as maintain and monitor various assets as part of a predefined service or maintenance procedure.

Try it for free

It’s easy to get started with QRmaint

And it’s free for 14 days. No credit card, no commitment.

Get to know the opinions of our clients!

The QRmaint CMMS system is a perfect solution for a number of industries, such as manufacturing plants, maintenance for real estate, chain stores, schools and all types of service providers. Have a look at what the representatives of different industries have to say about us.

The CMMS is a specialised software system that supports the work of maintenance and other departments. It enables production staff (operators, production leaders) to report faults and breakdowns from the production line to the Maintenance Department. The MD team receives immediate notifications on their phones and gets to work on rectifying the fault. The QRmaint CMMS tool significantly reduces response times to reported problems and makes it possible to delegate orders to specific technicians.

Another process handled by the tool is preventive plans, i.e. all kinds of machine inspections, legalisations and calibrations or rounds. In an average-sized production facility, prevention is about 60% of the MD team’s task. It is practically impossible to control them with an Excel spreadsheet which results in skipped reviews even for critical machines.

The QRmaint CMMS system is SaaS software, available in the cloud. Data is stored on the secure servers of the largest infrastructure provider Amazon Cloud Computing Services.

Data security is taken care of by Hostersi Company staff and our in-house specialists. Hostersi is an official Amazon AWS (Amazon Web Services) partner for the implementation of cloud computing and the reselling of AWS services. As an Amazon AWS Partner in Poland, we have the relevant knowledge, know-how and AWS certification to ensure the high quality of our services.

With the proliferation of the internet and the cloud-based software distribution model, the cost of a CMMS is no longer a burden even for small production facilities. Such software does not require its technical infrastructure and IT department. The maintenance processes in a small plant are identical to those in a large one, so implementing a CMMS will significantly increase the efficiency of the maintenance department.

The time taken to implement a CMMS depends on many factors, e.g. the size of the plant, and the number of processes to be supported. Implementation with the support of an experienced consultant does not usually take more than a few days and consists of the following steps:

- Initial configuration

- Introduction of the plant location structure and equipment from the machinery park

- Setting up accounts for colleagues (technicians, UR masters, production masters)

- Introduction of machinery prevention plans

The implementation of QRmaint is producing measurable results practically week by week in terms of improved communication between production and maintenance. Failure reports are standardized and collected at one location, greatly accelerating their processing. QRmaint focuses on mobility and working in “real time”.

The immediate benefits will include:

- Fewer failures in the production site.

- Reducing the number of unplanned machinery stops and reducing their duration.

- Reduction of service team response time in the event of failures with immediate notifications.

- Full control of planned maintenance on machines.

- Improvement of communication between production and service personnel.

- Increase of productivity in maintenance personnel.

- Full control of spare parts inventory

- Reporting of machinery failures and defects.

- Preventive maintenance planning

- Mobile access to the repair history for machinery and facilities.

- Assigning work orders/tasks to maintenance technicians

- Monitoring the spare parts inventories.

- Tracking of key maintenance indicators

The QRmaint CMMS tool lets you implement and exploit the full potential of Lean Management methods: Total Productive Maintenance, Kaizen, 5s, SMED.