The QRmaint system offers a number of functions that not only facilitate everyday work, but also allow you to automate many routine activities.

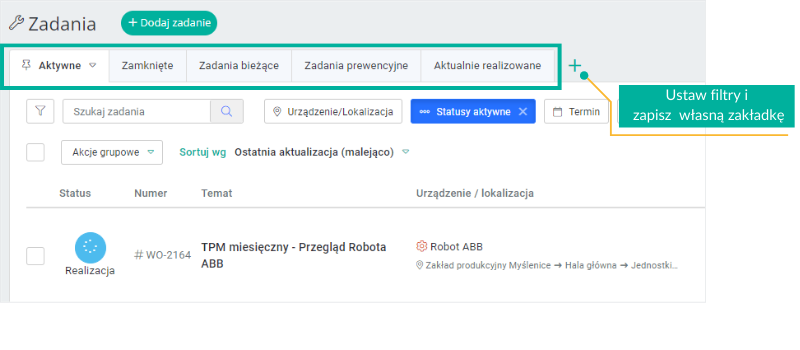

- Tabs – custom views of the Work Order list

The work coordinator deals with managing a large number of tickets on a daily basis, is responsible for supervising preventive Work Orders and monitors the progress of Work Orders assigned to technicians.

The list of duties is extensive, which makes it worth dividing it into groups. In this context, Tabs are helpful , which are a personalized view of the Work Order list, organized according to previously set filters. Thanks to them, the Maintenance Master can quickly access specific types of Work Orders and focus on important aspects of their implementation. Tabs allow for effective grouping of work orders, while facilitating their monitoring and management.

- Form settings – standardization of reports

The report must contain a complete set of detailed information, which is verified by the foreman before assigning the Work Order to a technician. QRmaint allows you to customize the form and indicate required fields, among others in the report form. Standardization of reports eliminates the step of their verification by the foreman.

Read how to configure forms - Automation Automation

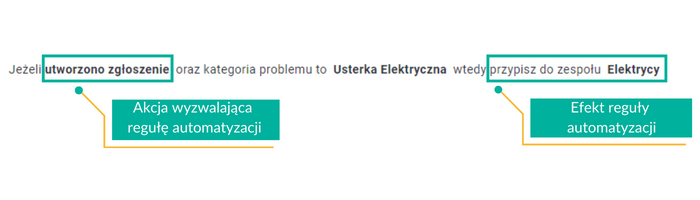

is the key to efficiency and reducing workload. QRmaint allows you to create automation rules thanks to which the system will, for example, automatically assign a team, set a deadline or add a checklist required for a specific type of failure.

You can learn how to add an automation rule in the entry Adding an automation rule

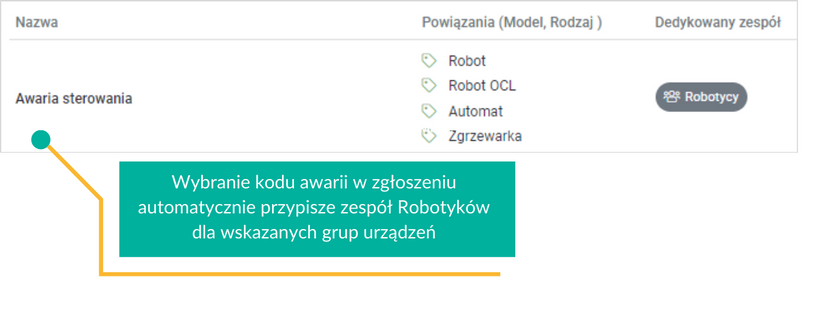

In the context of delegating Work Orders and automatic assignment to teams, the following come in handy:- Failure and fault codes

In the application form, the reporting party will be able to choose from a short list of the most common problems for machines from a specific group. The system will automatically assign a team dedicated to their service.

ⓘ Tip

ⓘ Tip

We recommend spending time developing a list of the most common machine faults.

Each machine group has specific and repeatable faults that generate over

80% of fault reports. Selecting these faults from a ready list, instead of describing them

with text, significantly simplifies Work Order management and allows for more effective

report analysis.

The list of fault codes and faults is created by maintenance together with production area leaders

- Problem Category

If the plant does not have a ready list of codes and failures, it is recommended to introduce a field called problem category into the ticket form. This is a list of general problem categories, such as mechanical or electrical faults. This allows the automation rule to automatically assign the Work Order to the appropriate team based on the selected categories.

- Failure and fault codes