23.09.2024

Transport & Logistics in Gent: QRmaint visiting Belgium

After a long holiday break is over now, industrial events around Europe have started again. The QRmaint team has a brilliant opportunity to visit the latest event in Gent, Belgium, dedicated to Transport & Logistics, Industrial buildings, and the manufacturing industry. The Transportation & Logistics event in Gent took place between 17-18 Sept 2024 and was an incredible opportunity to see the latest logistics manufacturing and construction trends. It is always good to visit your neighbors on the West side of Europe and see how our friends are running their operations.

In this article, we’ll give you a short wrap-up of this very interesting event in Belgium. We’ll share our insights about developments in the industry per sector. We’ll outline our perspective for perhaps future attendance at such events. Primarily, we’ll share why CMMS software is still a good match for manufacturing companies. All that is in this article. So, let’s buckle up!

Table of Contents

What about logistics and manufacturing in Gent?

The event was undoubtedly strictly dedicated to the Transport and Logistics industry. The leading name speaks for itself, but it is important to mention that it was combined with two other events. So, we could align with professionals from several industries under a single roof.

The entire event was combined with these three sectors:

Transport & Logistics: This company is solely dedicated to the transportation, warehousing, and logistics industries. We could meet companies that deliver assortments and equipment for warehouses. Among transportation companies, there were those solely focused on intermodal transportation, freight forwarding, and supply chain management.

Logistics & Industrial Build: A sector dedicated to the construction industry involved in building and administering warehouses and distribution centers. Several companies offered complete project management for the construction industry.

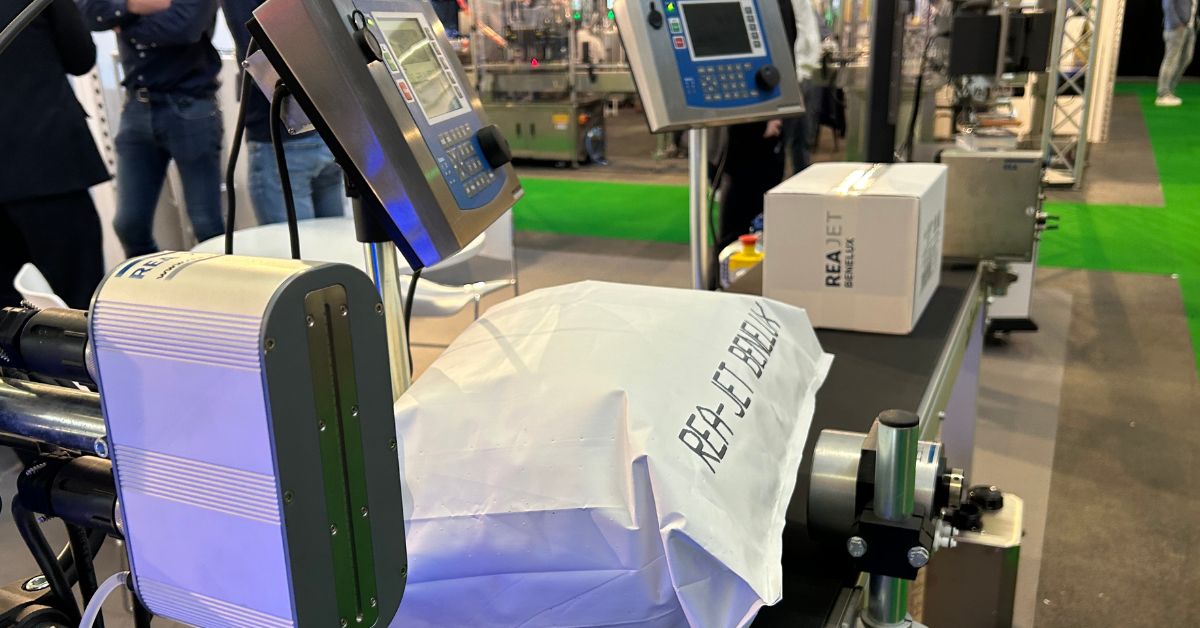

EMPACK: This sector was dedicated to automation and producers of packaging machinery in the manufacturing industry. Many highly advanced packaging machinery are driving changes in today’s industry.

Here the key highlights from the event with important figures:

- The event offered a complete overview of the supply chain and the needs of the manufacturing industry. More than 200 exhibitors and partners could provide a 360-degree view of the industry.

- During the event, there was a chance to align with part of the 6,000 professionals, which was an estimation of the total number of visitors to the event. There was a brilliant opportunity to benefit from their knowledge and experience over three days.

- Undoubtedly, the event in Gent allowed us to explore 15,000 sq. ft. of innovative solutions. This means that in this space, we could really see the world of opportunities for industrial growth.

- There were many conferences where over 50 experts shared their vision of the industry’s future. Hearing from keynote speakers about their insights on the significant problems in the manufacturing and logistics industries was terrific.

- Looking at the number of IT companies at the venue, we can see that digital transformation is now a vast part of each industry—nothing surprising to anyone anymore. We can explore the latest digital tools and solutions that are revolutionizing supply chain management and manufacturing, all in the presence of IoT, AI, blockchain, and automation solutions.

- There is a growing demand for IT infrastructure in every industry, whether logistics or manufacturing. During the event, Belgian companies discovered cutting-edge IT infrastructure solutions designed to enhance efficiency, security, and scalability in logistics operations.

- Event EMPAC was rich in the exposition of emerging technologies. Visitors could stay ahead of the curve by exploring emerging technologies like autonomous vehicles, packaging machinery with adjustable modules, and drone systems that foster rapid growth in logistics and manufacturing.

Manufacturing Industry and IT Infrastructure at EMPACK

We already mentioned this, but as our company’s profile aligns more closely with the manufacturing industry, we want to elaborate on this subject much more. We believe you’ll find it interesting, as during the event, we could really hear about the struggles of local companies regarding IT infrastructure and how systems can help support day-to-day operations in manufacturing.

By visiting the sector at the venue dedicated to EMPACK, we decided to tweak the purpose of our exploration and ask about the struggles companies face with maintaining their packing machinery. So, even though companies are coming to offer their unique and innovative machinery, it’s important to remember that many of these companies are also manufacturers of this machinery. They have production lines, assembly lines, and spare parts warehouses—all of which allow them to design and build modern machinery from scratch that helps pack various goods, liquids, etc.

By talking to engineers, IT experts, automation experts, project managers, and even manufacturing directors, we found that companies desire several elements to set up their production. Below is an outlook of what we learned about.

Critical Elements for Setting Up Production: Insights from Industry Experts

Based on conversations with engineers, IT experts, automation experts, project managers, and manufacturing directors, here are the key elements companies often prioritize when setting up their production:

Business should be focused on scalability and flexibility

Hearing from experts about adaptability to change was one of the most vital outcomes. Recent events in Europe and worldwide have signaled to companies that the ability to adjust production lines to accommodate new products, tackle decreases in demand, or respond to changes in market conditions is crucial. An aspect closely related to machinery building was modularity. Companies today are more focused on modular designs that allow for easy expansion or reconfiguration of production lines. This aligns with the scalability needs of both suppliers and companies that directly manufacture and use machinery.

Gain higher efficiency and productivity

Manufacturing is highly connected to developments in automation. Each assembly line should be implanted with automation technologies to streamline processes. It’s necessary to reduce manual labor and minimize errors often caused by human mistakes. This goes hand in hand with continuous improvement and lean manufacturing. Manufacturers constantly adopt lean principles to eliminate waste and improve workflow, guiding employees through more transparent processes.

Quality and Consistency

Each manufacturer clearly wants to deliver high-quality equipment and machinery to ensure customer retention. Therefore, they are focused on quality control systems. Most companies have implemented robust quality control measures to ensure products meet specifications and standards. Along with this comes the need for accurate traceability. Each company is building an extensive database of historical events to maintain traceability throughout the production process. This helps identify and address any quality issues.

Summary

The Transport & Logistics event in Gent was an amazing opportunity to see recent developments in Central Europe regarding trends and technology. By examining the needs of certain manufacturing businesses, we found that our CMMS system is a perfect match for their requirements. Nevertheless, it’s up to each company to determine what they truly need. To learn more about our QRmaint CMMS system, visit our page here and see what best fits your industry.

In summary, we highly recommend attending the future EMPACK and Transport & Logistics events. You will truly benefit from the fantastic atmosphere and the friendly approach of both the organizers and visitors.