25.03.2024

LogiMAT 2024 – logistics and maintenance trade fair

Table of Contents

What will you learn in this article?

On March 19/20/21, 2024, in Stuttgart, the trade fair LogiMAT took place, dedicated to various industries, including logistics, IT, manufacturing, maintenance, and automatation. During the trade show, visitors could learn more about the current developments in the each industry. From our perspective as a company specializing in software for services and maintenance, we saw great potential for our solution, not only in the German market but also worldwide. See the wrap of the event from our perspective.

Global fair LogiMAT 2024

LogiMAT gained broad recognition as the International Trade Show for Intralogistics Solutions and Process Management. This year’s edition attracted 101,649 visitors, exhibitors, media representatives, and over 67,420 industry professionals, representing a significant increase of over 10% compared to previous years. We observed over 1.6K exhibitors while they presented their latest production and solutions dedicated to various industries.

The venue covered about 67,000 square meters, where companies worldwide could showcase their brilliant solutions. They were exposed to 9 general sectors divided into packaging, packaging materials and machinery, order-picking systems, fleet management, Automated Guided Vehicles, robotics, labeling and printing, identification, loading technologies, and door systems.

A common characteristic of every piece of equipment, machinery, and robotics presented was tightly demanded software solutions, as well as particular tasks that needed to keep the operations up and running. No matter what kind of equipment and machinery are in use, being an operational manager often requires taking responsibility for service and maintenance.

LogiMAT for service & maintenance

During the event, we could see a significant shift in today’s logistics towards automation. This element was evident not only through autonomous robots dedicated to supporting logistics operations and reducing manual workload but also through automated shelving with software-guided rollers designed to store goods directly in warehouse locations without human touch. Companies such as Axmann Fördersysteme GmbH, Nedcon, and Movu Robotics have presented their solutions in this segment.

Robotic arm presented during the event in Stuttgart.

Such equipment is being increasingly implemented in many warehouses worldwide, including those directly connected to manufacturing plants. Its extended complexity requires constant attention to provide the best capacity and integrate business processes such as just-in-sequence or just-in-time delivery, where required goods are moving only in the amount that is needed for production and on time.

Modern storage and production racking system.

The complexity and high requirements for a wide range of components drive the rising need for service and maintenance of the entire infrastructure. This infrastructure is often connected to warehouses with automated roller conveyor systems that frequently deliver raw materials to assembly or production from the warehouse sector. These are also not exceptions; furthermore, they connect to robots installed along the conveyor rollers.

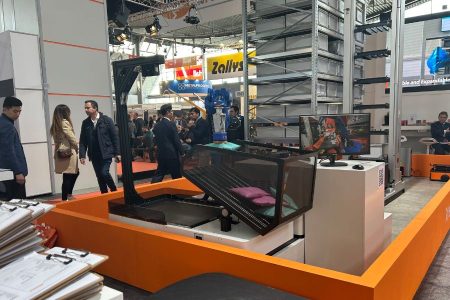

Autonomous Vehicles presented at the event.

An effective system such as CMMS is needed. It is usually helpful in keeping the production line in order. However, in this scenario, its role is extended to facility management functions. In this way, CMMS can provide full coverage for the service and maintenance of automated warehouses and all equipment, infrastructure, and machinery required for production.

Experts Forum on LogiMAT Arena

As always, during the event, we could hear from industrial experts who understand the current state of developments best. By listening to them, we could hear forecasts that firmly confirmed the unstoppable change toward digitization across all industries.

Keep an eye on our focus area, which is service and maintenance along with the CMMS system; on Tuesday, 19.03.2024, we could listen to the Logistics for Fluid Production panel. Among the speakers, we have heard from Ali Bozkurt, Research Assistant, Institute of Mechanical Handling and Logistics, University of Stuttgart, about Fluid production logistics—opportunities and challenges. The second speaker, Benedikt Feldotto, Project Director, Software-Defined Factory Operations, Corporate Research, Robert Bosch GmbH shared about adaptability through software-defined manufacturing in the Bosch Factory of the Future, and the third one, Bernd Neuschwander, Team Manager, Advanced Development, explained Innovative methods for securing mobile production units—shared safety.

Keynotes at LogiMAT 2024

This panel discussed the manufacturing sector. The speakers moved on to variable production methods, such as fluid manufacturing, which creates opportunities for the flexibility and adaptation required to meet dynamic demands. However, this cannot happen without using the right logistics.

Our conclusion from this forum was that various aspects of logistics in fluid manufacturing cover well-tailored hardware and software components. This was a key takeaway: by knowing better fluid production logistics—opportunities and challenges- we can better integrate all business units. These cannot function alone in a production plant without supportive software that helps keep equipment and machinery in good operational condition.

Final takeaway

During the event, we observed how many companies are progressing towards modern technologies. Nevertheless, in today’s uncertain times, many technologies presented at Messe Stuttgart still seem pretty new in manufacturing, whether we’re talking about machinery or software. Many producers are focused on developing highly productive equipment, but they still need to fully address the approach for future operational needs of this equipment.

Wear parts, errors, and machinery failures are common problems that cannot be entirely prevented or predicted. Therefore, companies will still need to have maintenance programs in place to keep operations up and running. Deploying facility systems to support infrastructure, or CMMS systems in production plants, is vital in business management to protect assets against expensive losses.

QRmaint was delighted to visit this incredible event. LogiMAT will be our focus in the next few years. It was great to see all the companies responsible for developing the manufacturing sector.