22.03.2024

Top 10 features of a CMMS System

Table of Contents

What will you learn in this article?

In this article, we present the top 10 features of a Computerized Maintenance Management System (CMMS) for manufacturing. We discuss under what circumstances specific CMMS features are required and how they can be modified to flexibly adapt to the individual needs of a business. You will also learn how to choose the right CMMS and which features should be included to enhance your company’s efficiency.

From this article, you will learn about these CMMS features:

- Fault and defect reporting

- Task delegation to technicians and execution (task management)

- Checklist management

- Preventive tasks – planning inspections and monitoring them

- Equipment detail overview

- Spare parts inventory management

- Requisitions – submitting requisitions by technicians

- TV Dashboard

- Interactive plans

- Reports

Leveraging a CMMS and digital transformation in business

Many companies in the industry today face a dilemma related to digital transformation. The question is no longer whether to opt for a system that supports management and operations but rather which system is most suitable. Choosing systems like a CMMS for manufacturing enterprises is inevitably the future in an era of digitization and process automation. Nonetheless, for many businesses, finding the right maintenance management system is not an easy task.

A CMMS (Computerized Maintenance Management System) should encompass specific features to best adapt to a company’s operational activities. An important aspect of a CMMS’s functionality is also its adaptability. This is because some industries have relatively different production processes and production line equipment. Therefore, it is crucial that a company’s processes are well mapped out, significantly easing the definition of the scope of needed CMMS features and the area of modifications that should be implemented. This is intended to better tailor CMMS features to the nature of operations within a company, and sometimes even to integrate with external operations.

Key needs of manufacturing enterprises in the context of digitalization include:

- The need for better organization of production processes and maintenance management

- Implementation of a reporting and maintenance management system

- A system for preventive actions, maintenance of infrastructure, and equipment (machines, tanks, pumps, etc.).

- Improving communication between production line operators and the maintenance team.

- The need for monitoring work and a system for calculating indicators

- Handling fault reports and periodic maintenance service of machines

- Notifications, preventive maintenance, spare parts inventory management

- Integration of the maintenance system with the ERP system

- Management of technicians and maintenance staff

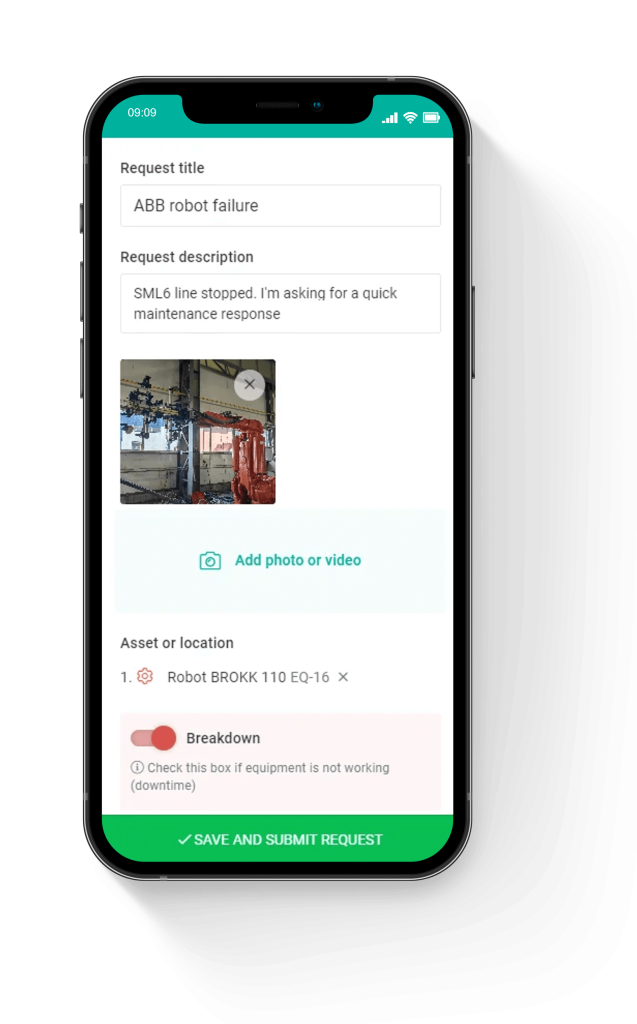

Reporting faults and failures with the CMMS system

Fault and defect reporting with a CMMS

The fault reporting system should identify the problem, its cause, and designate corrective actions for each report. The task group of the maintenance team, responsible for equipment maintenance and repair during failures, can demonstrate effectiveness in detailed problem identification and corrective actions only when it has a CMMS equipped with fault and defect reporting functionality.

The fault and defect reporting feature in a CMMS is primarily used for identifying problems and their causes, as well as determining short- and long-term corrective actions. All errors, defects, and failures should be defined using an individual fault code, which allows for faster identification of the most common types of irregularities and more accurate and quicker service handling of reports.

The most common types of production issues identified by fault codes include:

- Malfunction

- Operator error

- Improper handling

- Electrical fault

- Mechanical fault

- Regulatory report

- Lack of signal from sensor

- Absence of measurement program

- Faulty component

- Camera or sensor fault

Coding can also apply to individual tasks and activities that need to be carried out. The most common tasks performed by technicians and the maintenance team following a fault or failure report include:

- Adjustment of devices or machine components

- Part regeneration

- Calibration of sensors and measuring subassemblies (among others)

- Machine rebuilds and relocations (mainly to reduce downtime of non-operational machines that have failed, etc.)

- Procurement of consumables (e.g., tools from the warehouse or stock for the job)

- Perform lubrication

- Diagnose the problem

- Modify equipment

- Conduct disassembly

- Preventive/preventative measures

- Dismounting and replacing parts

- Repair of the device

- Remove and reinstall a component

- Conduct inspections

- Install a new part or subassembly

These are general maintenance activities, which in a CMMS system have specific identification codes that streamline later efforts to address issues, for example, with the production line or failures, etc.

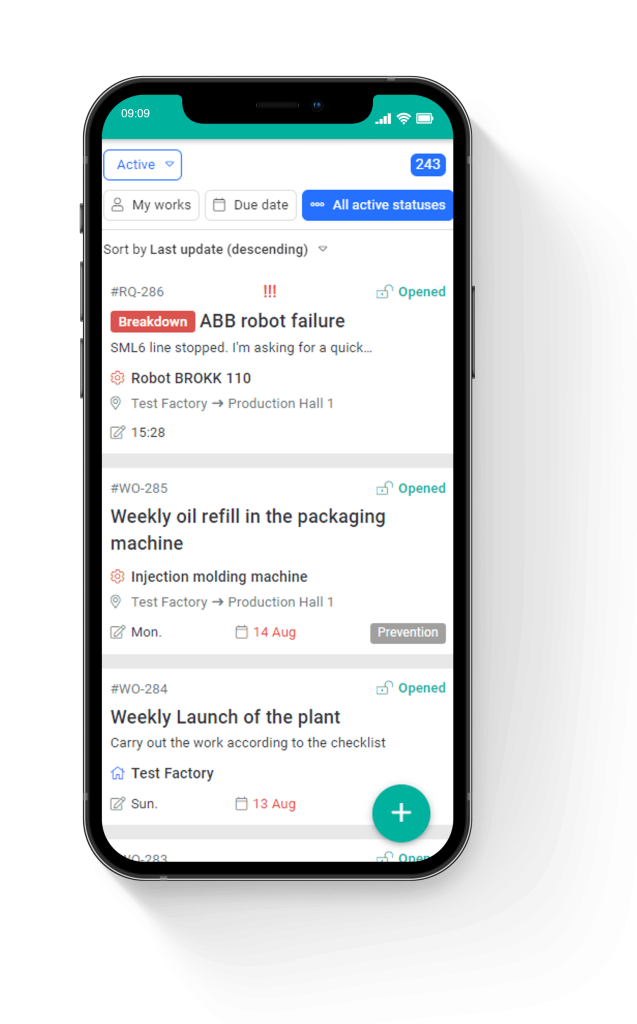

The CMMS system facilitates task delegation to technicians

Task management with a CMMS: delegating tasks to technicians and execution

In the past as well as today, task management has been carried out according to a schedule developed in advance, for example, for service activities. However, in the past, many tasks were performed using forms on paper lists. As a result, many problems and difficulties arose, not only due to the lack of quick tracking of work but also due to the absence of maintenance action verification. Another issue was the frequent loss of data due to the destruction or misplacement of the form.

Furthermore, there were also problems with organizing the action plan and reorganizing and allocating resources. In this case, it’s not just about managing the technicians’ work and their time, but about allocating the necessary work tools for carrying out repair actions. Previously, work largely resembled firefighting by moving resources to where they were most needed.

Today’s CMMS enables managing work and automatically assigning tasks and tracking work progress in a more harmonized manner. Moreover, technicians have the opportunity to perform tasks in the most favorable form, with access to the spare parts inventory and instructions on how to perform the work with just one click in a mobile app.

In a CMMS, a maintenance technician can:

- Check active tasks

- Schedule preventive, reactive tasks

- Get an overview of machine users

- Monitor task status (closed, to-do, currently in progress)

- Set task priorities

- Arrange group actions (e.g., a repair activity requiring more than one person)

- Make changes to schedules and set repair calendar dates

- Organize technician tasks and control working hours

- Take photos and record videos of the work being conducted

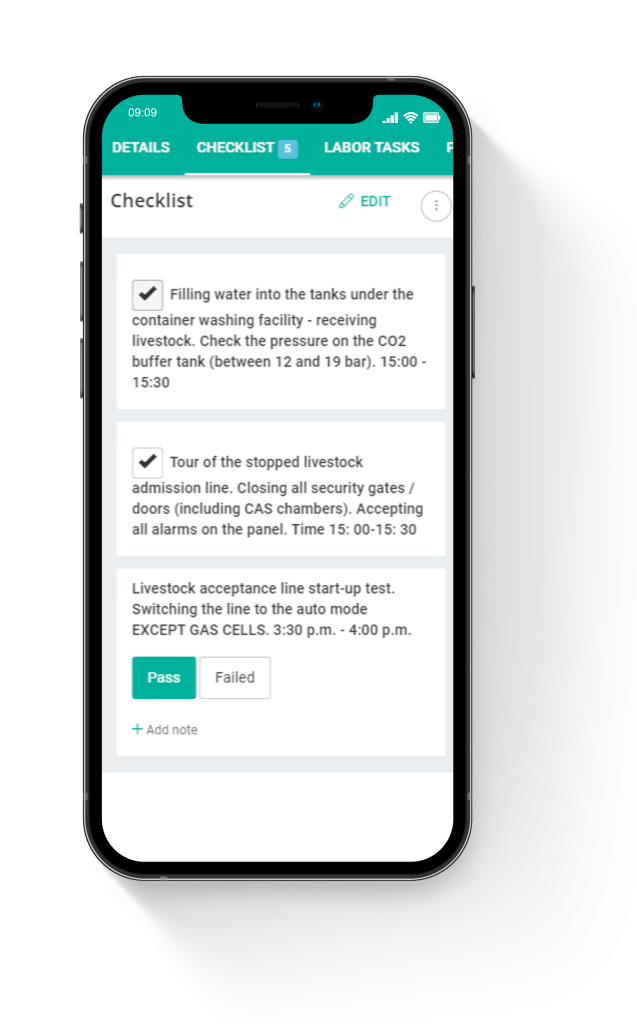

Checklist view in the CMMS system

Checklist management in a CMMS

Checklists have always accompanied maintenance technicians in their paper form. In the era of digitization and modern CMMS systems, their scope has expanded far beyond the control of inventory levels and the inspection or service tasks performed on machines and equipment in factories.

Today, a CMMS offers a significant set of features and checklists, which provide users not just with data about the tasks being performed but also with views into the inventory status with precise photos of components, recorded videos of maintenance work, and detailed descriptions. Here are some of the details that checklists can include:

- Device identification number

- Device name

- Product/equipment group/class

- Location

- Usage meter reading

- Periods for preventive maintenance and servicing or repairs

- Daily usage

- Date of the last maintenance and repair

- Schedule for upcoming work

- Cycle time for maintenance and repair

- Required units, number of people, and time for each

- Required parts and tools

Checklists can be supported by QR codes, which, placed on devices and in the inventory, help identify the condition of the equipment and better control the quantities of spare parts in stock.

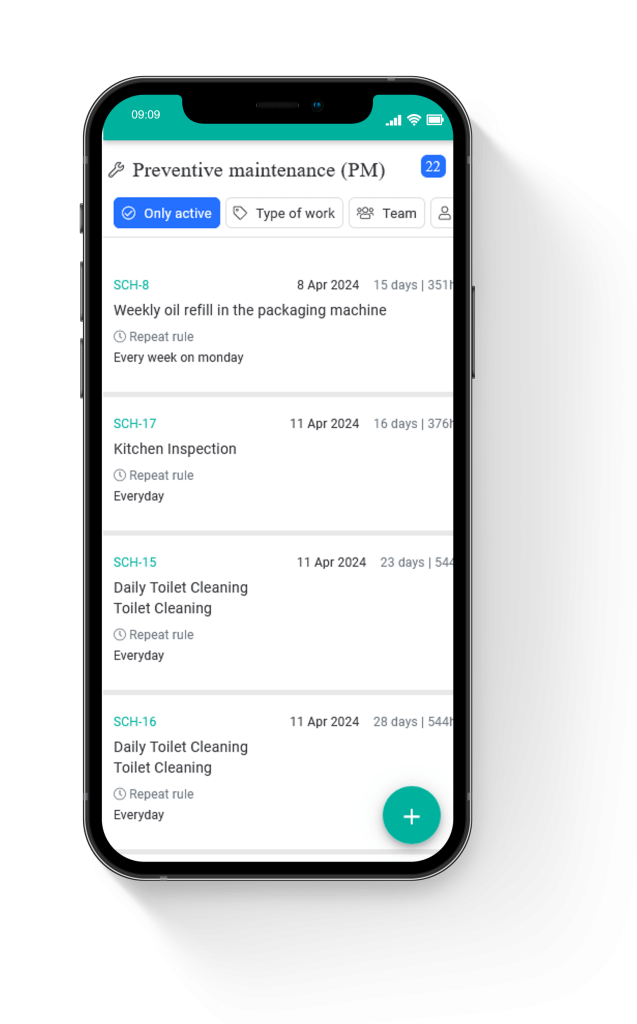

Preventive tasks allow for the scheduling of inspections

Preventive tasks in CMMS: planning inspections and monitoring

Monitoring condition and inspections are part of preventive maintenance activities. These activities are defined as all tasks related to the use of modern techniques to accurately diagnose the condition of equipment during operation.

To conduct inspections and monitoring at the highest level, periodic measurement and compilation of process or machine parameters are required to predict failures before they occur. To achieve this, maintenance personnel utilize a CMMS system with a function dedicated to preventive tasks.

Preventive actions with a CMMS application include visual inspection, functional tests, and checking the condition of materials. Preventive tasks carried out in a CMMS system can include options for:

- Task type (allowing to specify the task being performed: failure, malfunction, review, etc.)

- Setting task priorities

- Selecting specialists for the team

- Establishing rules (working time and/or measurement reading)

- Choosing the location and device

- Determining the criticality of the problem

- Selecting the type of device

- Creating a notification for the required machine shutdown

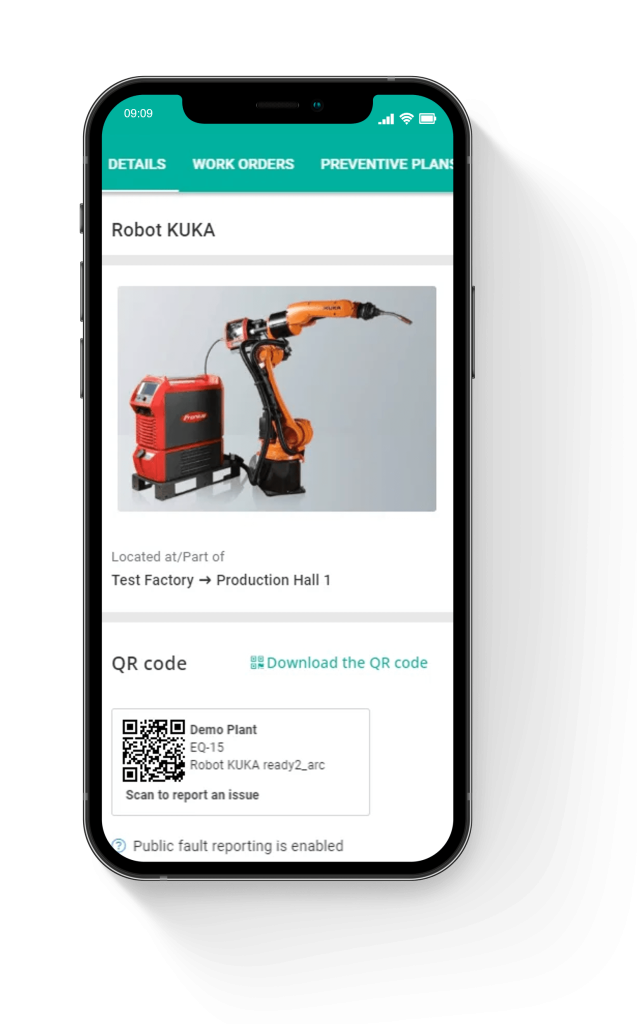

Viewing device details in the CMMS system

Equipment detail overview in a CMMS System

Knowledge of equipment characteristics is above all one of the most important elements of maintenance work. Repairs, servicing, and maintenance cannot be done without the technician’s knowledge of the detailed construction of machines, components, and materials. Hence, it is crucial to gather all information about the machinery park, production line from engineers who organized the equipment to have a complete set of technical documentation.

In a CMMS system, the function to view equipment details is not only to provide technical data about the equipment but also to track all work performed on machines and devices, such as repairs and servicing. The technician then has access to the entire history and precise data, including who operated the machine and who conducted service or repair work, among other details.

Within a CMMS application, we can access the following data:

- Active devices

- Select a specific facility (if there are multiple production locations)

- Monitor machine downtime

- Determine criticality

- Tag

- Specify the type of device

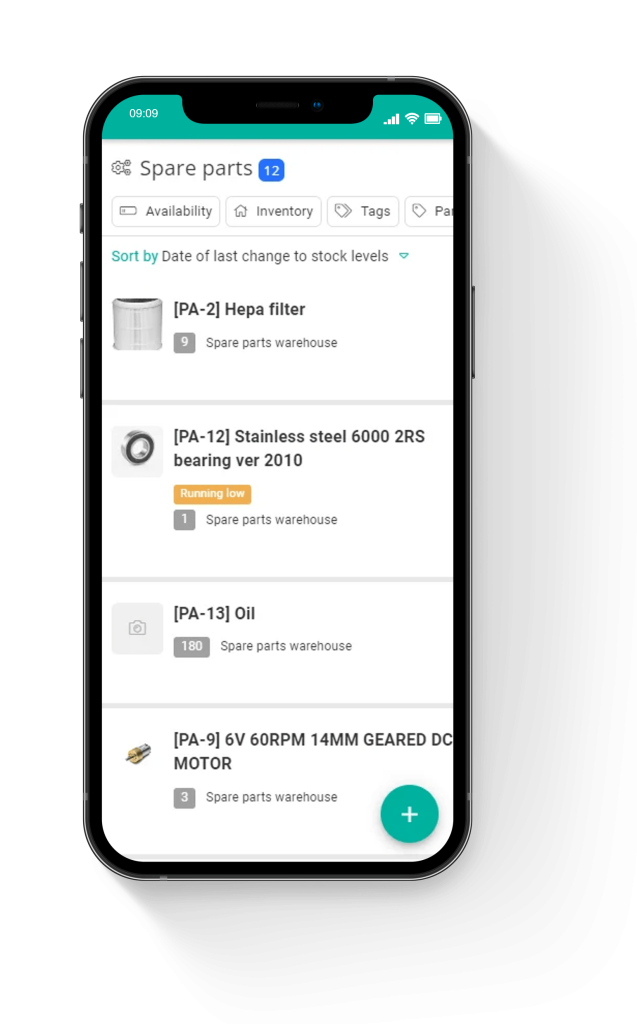

View of the spare parts warehouse

Spare parts inventory management with CMMS

Having an adequate stock of spare parts is crucial for manufacturing companies to avoid costly machine downtime. The absence of spare parts can be extremely expensive, but so can their surplus in terms of warehouse space and the cost of spare parts. For small components, this does not play a significant role, but for expensive materials, proper warehouse management has considerably greater value.

The parts warehouse should be integrated with the work of the maintenance technicians. The CMMS system function for managing a spare parts warehouse is an extremely important part of the maintenance team’s work.

Below we present some of the options and warehouse actions included in the CMMS system for managing the warehouse and streamlining technicians’ work:

- List of available parts with photos and full data

- Inventory status (spare parts warehouse, handy warehouse)

- Tool shop inventory

- Classification and type of parts

- Part manufacturer

- Critical components

- Inventory correction

- Part requisition in tasks

- Warehouse withdrawal

- Warehouse admission

- Inter-warehouse transfers

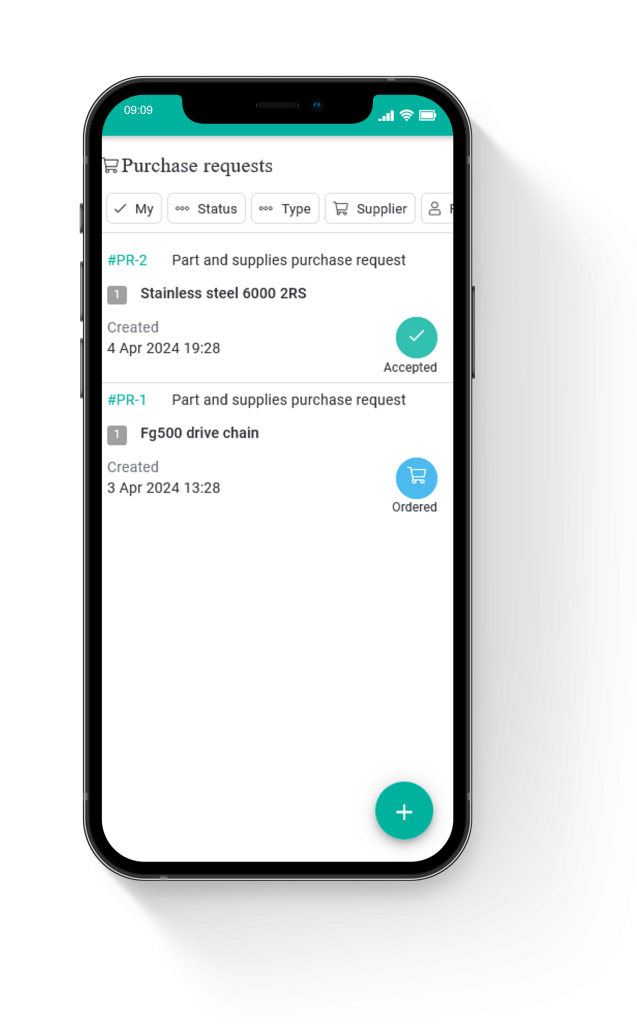

Fulfill requirements through the CMMS System

Requisitions through the CMMS System

Gathering requisitions for parts, components, and tools is one of the technician’s activities that streamline maintenance operations in daily tasks. However, to maximize the efficiency of this work, a CMMS system is required that allows for the integration of some technician work functions with warehouse operations.

A CMMS system’s mobile application enables the communication of a request sent by the technician to the warehouse, which can automatically verify the stock status and prepare the appropriate part for replacement or directly place an order with the supplier.

Below are some of the options available in the requisition function implemented by CMMS:

- New requisition (submit an inquiry for new parts)

- Status (define and check the execution status of the requisition: waiting for approval, approved, rejected, ordered, etc.)

- Requester (select a user)

- Requisition for parts and materials

- Requisition for services

- Purchase by the supplier

- Executor

- Supplier (specify the supplier)

Dashboard TV view on a tablet

TV Dashboard in the CMMS System

While working in production, it’s crucial to continually monitor the work status. The maintenance work status in large manufacturing plants is very complex. Therefore, it’s essential to closely monitor the technicians’ work in real-time.

This is one of the CMMS functions, the TV Dashboard, which operates by displaying operational data in real-time on a screen that can be installed both on the production floor and in the office or technicians’ room. Users can decide which data to display and freely modify the layout of the dashboard.

The TV Dashboard in the CMMS system allows for the display of data on:

- KPIs (Key Performance Indicators)

- Frequency and duration of repairs

- Number of failures

- Cleaning and disinfection

- Calls to production lines

The type of data displayed depends on the company’s needs. All data are presented in user-friendly graphical indicators, using diagrams.

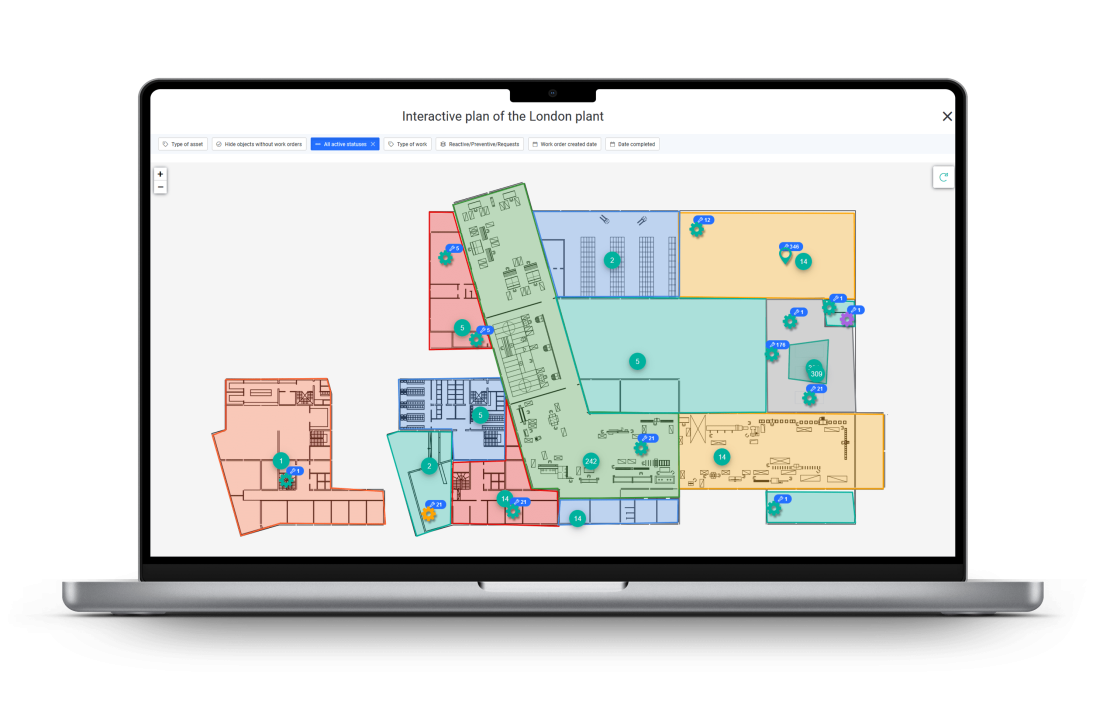

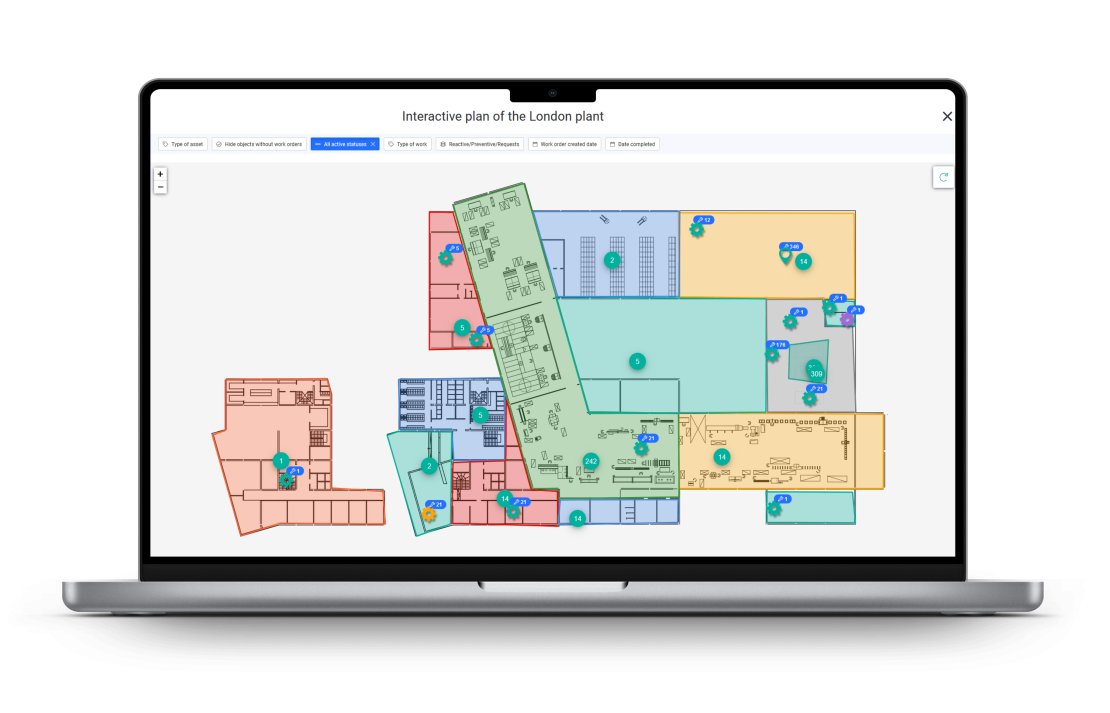

Overview of interactive plans in the CMMS system

Interactive plans in CMMS

Accurate mapping of the production area is crucial for better navigation and locating faults. One of the CMMS system functions allows for creating a graphical representation of the production area, which in 2D format presents a map of the company’s production area, including the location of machines.

Locations on the map can be tagged, thus the interactive plan of the production area allows the technician to continuously monitor the progress of maintenance activities.

Below we present the benefits of using interactive plans feature in a CMMS system:

- Improved work monitoring

- Graphical representation of the production area (more readable processes)

- Faster resolution and identification of problems on the production line

- Better tracking of technician positions and tasks

- Enhanced control of machine condition and status

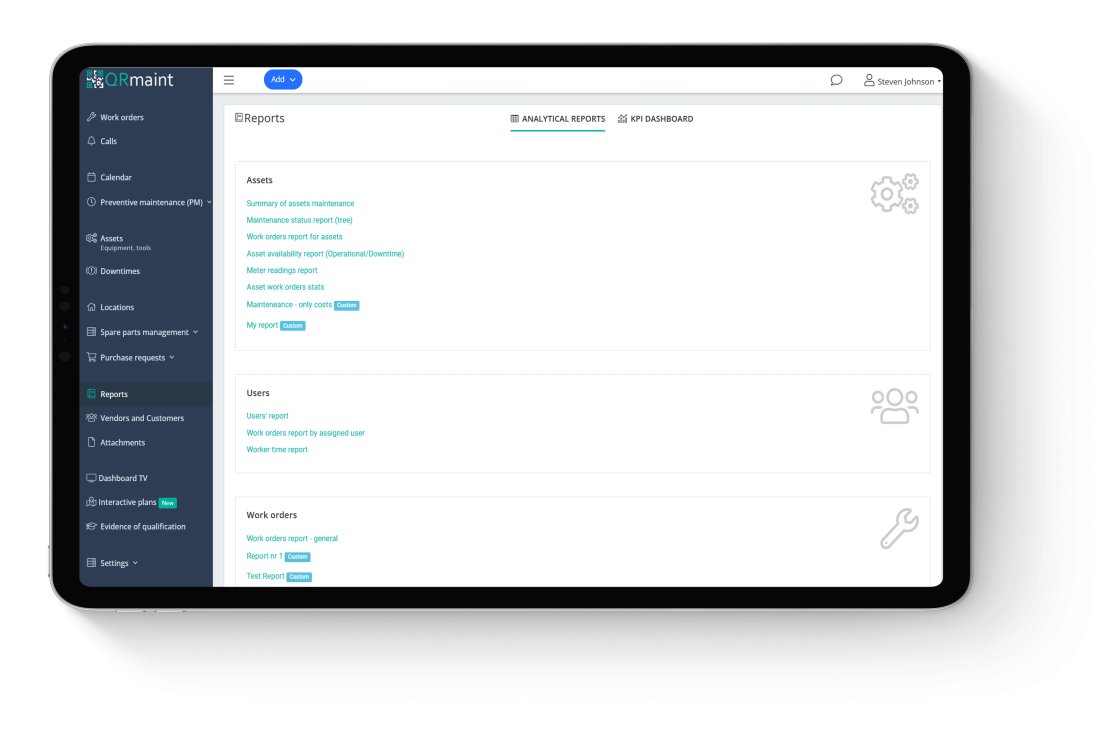

Generating reports through the CMMS system

Reports: generating reports through the CMMS System

Data collection is a very important part of maintenance work. Insight into actual data allows for better evaluation and prediction of maintenance tasks. Thanks to reports, we can better record working hours along with the use of spare parts. These elements contribute to better financial data for the company and more informed decisions.

One of the features of the CMMS system allows for generating reports according to company needs. Here are some of the benefits:

- Equipment maintenance summary

- Hierarchical maintenance status report

- Task report for the device

- Equipment availability report

- Summary of tasks for devices

- Quarterly report for devices

- Management report

- Daily downtime

- High-priority task report

Summary

A CMMS system allows for the implementation of a completely new and improved standard of maintenance work in a manufacturing company. The features we have presented are basic support for maintenance tasks to ensure work is carried out smoothly and easily. Individual features not only allow for efficient work monitoring but most importantly, improve the quality of work, which translates into greater savings for the company.

It is important to choose a CMMS system that allows for a certain degree of feature modification to better match the needs of the company. QRmaint is a CMMS system that includes all the 10 functions mentioned above and allows for their modification to better suit the company’s needs. QRmaint can be used on a trial basis for 14 days with all its features. Contact us today and test the mobile CMMS system in your company.