Tool for recording machine and equipment downtime

Record machine downtime and use reports on failures and equipment availability in the machine park, to better plan maintenance work.

Reduce downtime with QRmaint CMMS

This system is dedicated to maintenance teams, enabling the analysis of data gathered on machines and devices. This knowledge allows you to plan maintenance work appropriately and significantly reduce unplanned downtime of production lines.

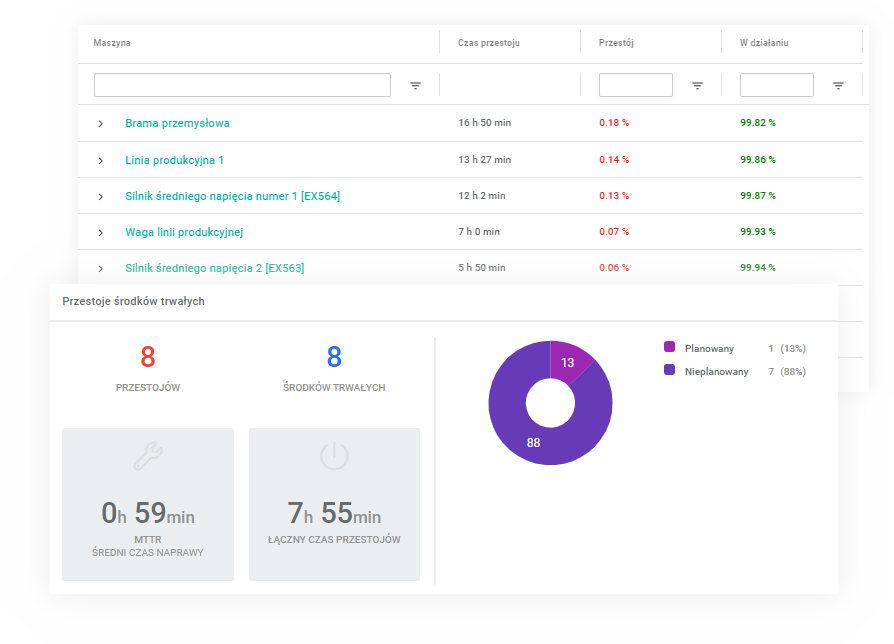

Analyze machine downtime

Make decisions on repair or replacement of key equipment in a production plant based on real data.

Report downtime in real time

Provide your machine operators with failure reporting made simple. They are the first to notice any defect, issue or failure.

Reduce downtime

Unplanned downtime is a waste for any manufacturing facility. Quick failure reporting to the maintenance department and automatic assignment to the technician reduces downtime by more than 60%.

It’s easy to get started with QRmaint

And it’s free for 14 days. No credit card, no commitment.

Precise downtime- at your disposal- thanks to the QRmaint CMMS mobile application

-

Provide machine operators with instant notification of downtime, thanks to the QRmaint CMMS mobile application

In the event of a failure, simply scan the QR code of the machine or select from the list on the phone or tablet.

-

Use notifications to inform the maintenance technicians about the failure of the machine

Notifications appearing on the phone allow you to significantly reduce the response time of the maintenance department and machine downtime.

-

Find out the real costs of production line downtime

A minute of downtime of a critical machine can cause significant losses, when it comes to both the production and the income. Tracking downtime will help you with planning and decision making.

Try it for free